2013

Founded in

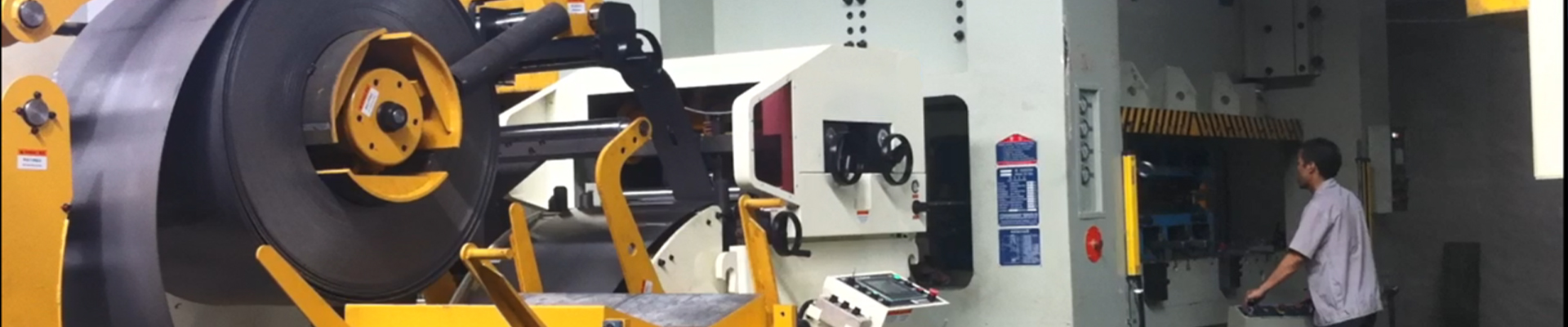

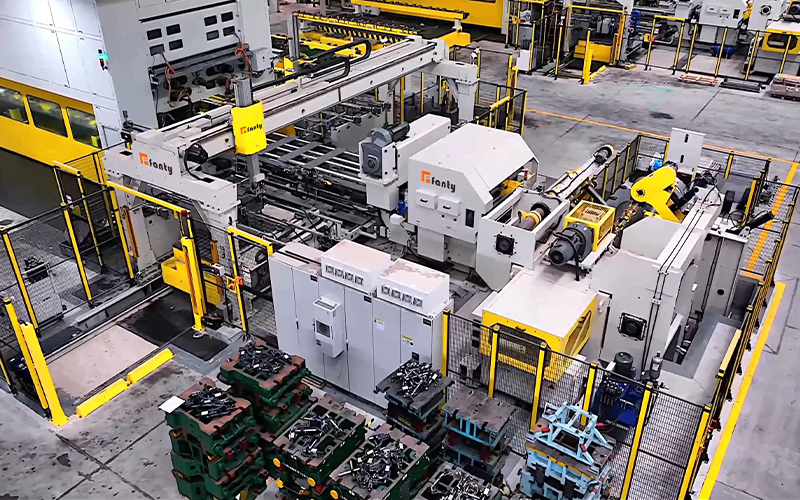

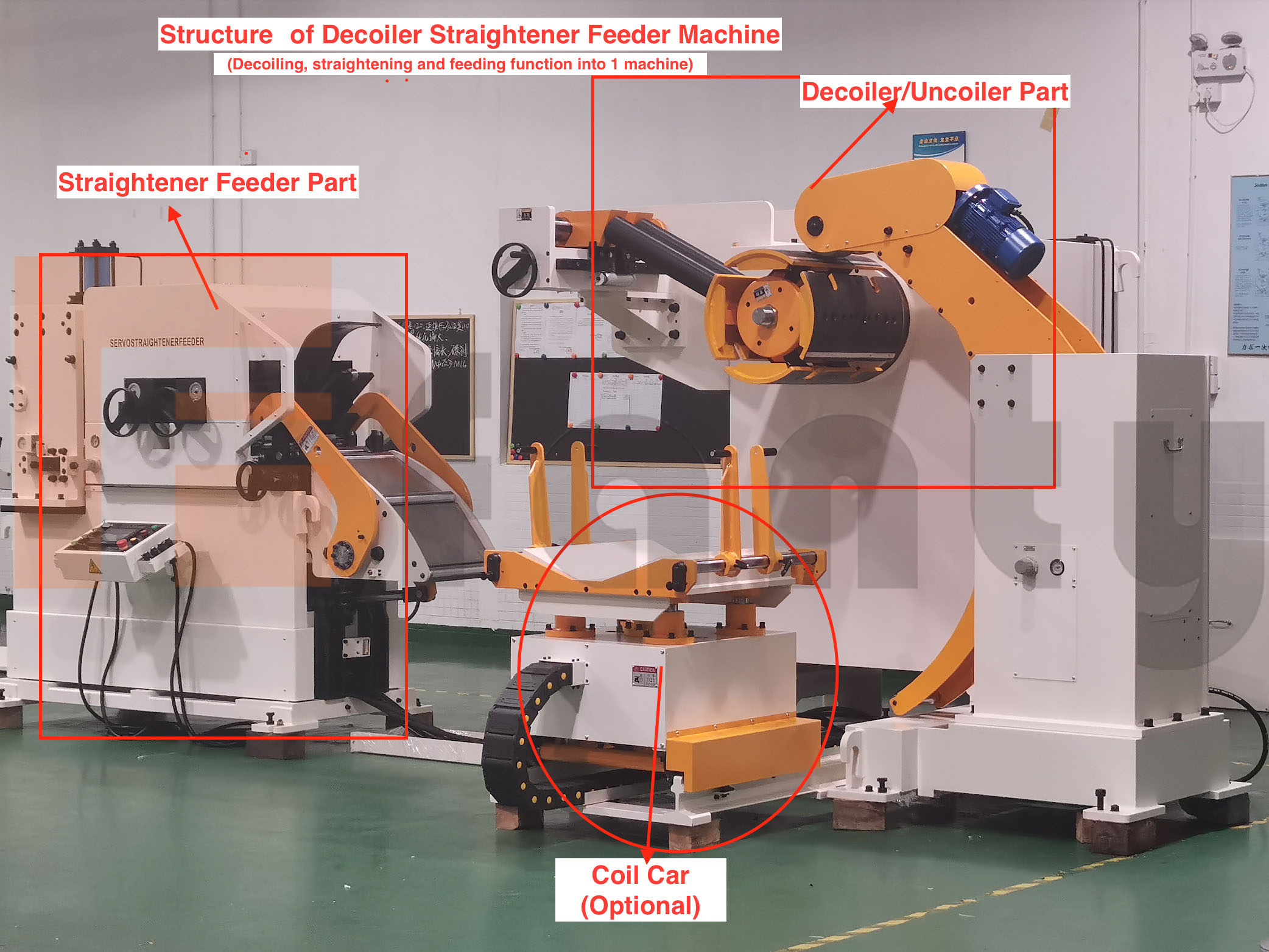

Fanty provides your perfect-match Metal Stamping Automation Equipments and metal stamping solution.

Founded in

Factory area

R&D Team

A: Fanty’s Metal Stamping Automation Equipments is widely used in industries such as automotive manufacturing, home appliances, construction materials, and hardware production. Our flexible and customized solutions meet diverse production needs.

A: Choosing the right equipment depends on factors like material thickness, width, weight, and stamping requirements. Our technical team offers free consultations and expert advice.

A: 1, Fanty provides end-to-end customized services, from Metal Stamping Automation Equipments' selection, design, and manufacturing to installation and commissioning, ensuring the equipment perfectly fits your production requirements.

2, OEM/ODM services.

3, Metal Stamping Automation Solution to your press line.

A: Fanty's metal Metal Stamping Automation Equipments is designed for stability and efficiency, utilizing advanced technologies to minimize maintenance needs and optimize production processes.

A: Fanty offers global technical support and fast-response after-sales services to ensure your issues are resolved promptly.