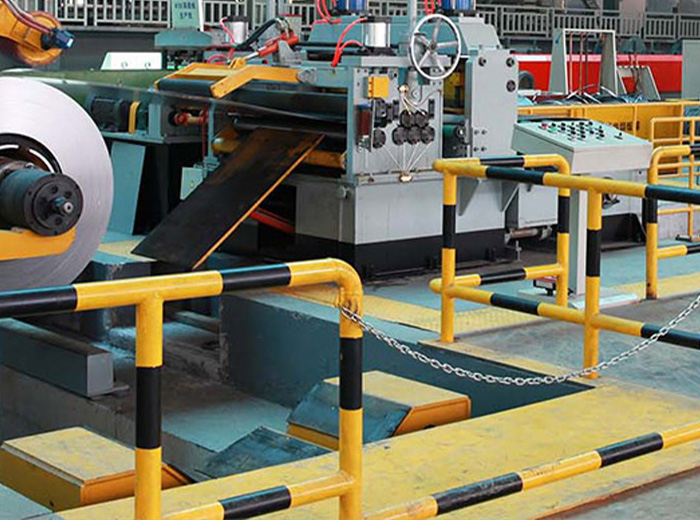

Uncoiling & Straightening

- The coil material is smoothly unwound through the uncoiling equipment (decoiler), then to straightener for leveling.

- Purpose: CTL line starts by uncoiling a metal coil, then leveling it by using a straightener.

Fanty has been specializing in the manufacturing of diverse cut-to-length line (CTL) solutions since 2013.

As the starting point of the CTL line, Coil is uncoiled smoothly by a decoiler that can handle coils of various weights, diameters, and widths.

After the metal strip is uncoiled, it typically needs to be straightened by a straightener to eliminate any curvature, bends, etc.

After coil leveled, in this step, then the metal coil will be handled by a coil feeder for a precision feeding.

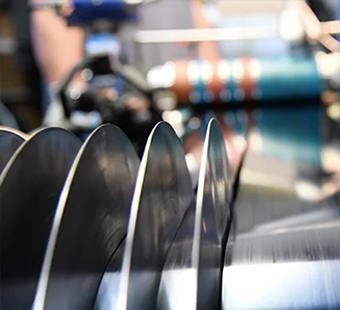

The metal strip is cut into sheets by a cutting mechanisms including shears and circular blades.

This may include deburring machines, edge rounding tools, or other devices that process the edges.

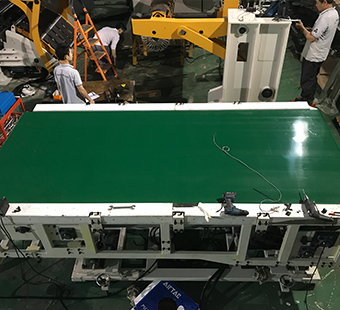

To transport the sheet for stacking from the cutting mechanism, then to the exit. By the conveyor, sheet can be moved smoothly and at a consistent speed.

This is the end of CTL. In this step, by a stacker, the cut sheets can be organized and stacked more efficient at the end of the line. Not a necessary for small CTL.

We are committed to help customers minimize production line downtime and improve metal stamping efficiency and save cost surely.

Our vision is to become become a global leader in metal stamping automation, driving industry more smart and efficient.

Committed to improving the efficiency of coil handling equipments and avoid material waste.

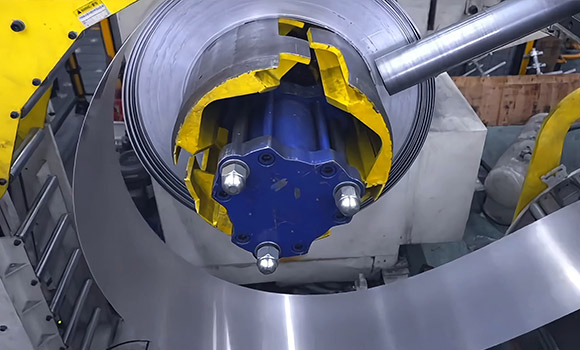

Handling the coil for uncoiling and straightening.

Moving/Lifting the coil safely & smoothly to the expansion structure of the spindle

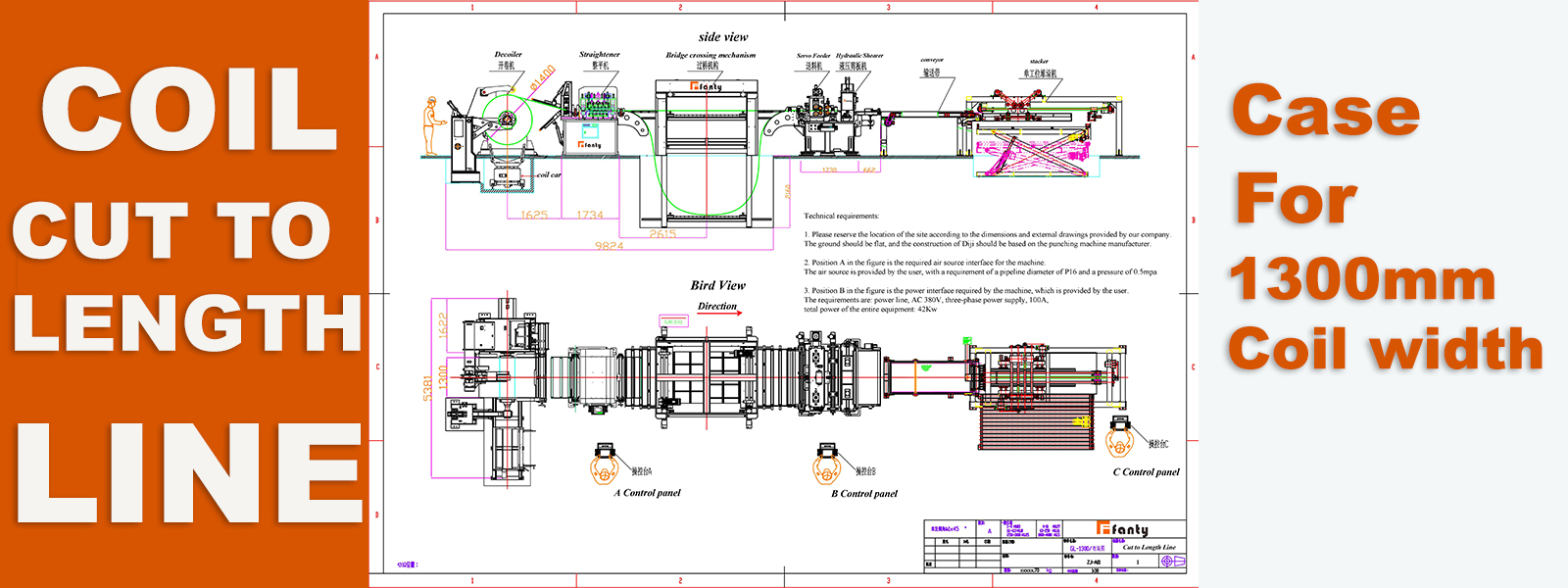

Coil Width: 300-1300mm

Coil Thickness: 0.5-4.5mm

Coil Loading weight: 10,000 kg

Maximum Outer Diameter: φ 1500mm

| Type | Belt Face Wide | Belt Machine Length | Transporting Velocity | Side Height |

|---|---|---|---|---|

| Stationary Type | 1,350 mm | 2,500 mm | Max.30 m/min | 30-100mm |

| Maximum Billet | Minimum Billet | Bullet Height | Bullet Weight | Coil Car |

|---|---|---|---|---|

| 1250×3200mm | 300×300 mm | Max.500 mm | Max.5000kgs | Hydraulic Lift Drive |

① Visual Inspection

② Cleaning

① Lubrication

② Tension Adjustment

① Alignment Check

② Electrical System Inspection

① Component Wear Assessment

② System Calibration

① Overhaul and Replacement

② Safety System Inspection

Answer: Our CTL lines are highly versatile. They can handle a wide range of materials, including various grades of steel, aluminum, and copper. However, the specific capabilities may vary depending on the model.

Answer: Most of our standard CTL lines are primarily designed for straight cuts. However, we do offer models or optional features that can perform angled cuts. For complex cuts, we can provide customized solutions.

Answer: Our CTL lines are designed to be highly compatible with a wide range of existing production equipment. We can ensure seamless integration with presses, welders, and other machinery in your production line.

Cover decoiler, coil feeder, uncoiler cum straightener, decoiler straightener feeder etc.

Having provided the Tailor-made coil cut to length lines since 2013.

Reliable service backup on pre-sales, sales consulting, after-sales.

Pls contact us fanty@sz-fanty.com for a detailed talk!