2013

Founded in

Businesses with proven expertise in metal coil processing and a focus on advancing industry standards.

Partners who prioritize quality and reliability, ensuring top-notch equipments and services for their customers.

Companies that share Fanty's dedication to high-quality standards, sustainable practices, and long-term success.

Believe in the excellent influence of Fanty.

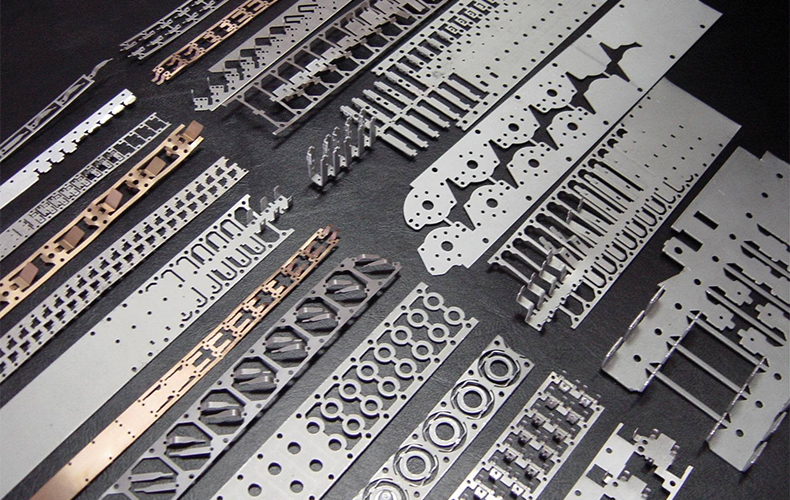

Tailored coil processing and metal stamping automation solutions to help your business streamline processes and improve metal stamping efficiency.

Get Fanty high quality metal stamping automation equipments and metal stamping automation technology to stay competitive in the evolving industry.

The team from Fanty's sales, R&D, Production, After-sales, is here to support you with sales, technical guidance, after-sales, and ongoing training.

Offers a wide range of metal stamping automation equipments parts options to support your local service.

Training sales and technicians to ensure proper equipments installation.

Install or sell a minimum number of metal stamping automation equipments per year to ensure familiarity to equipments.

Commitment to support the promotion of Fanty metal stamping automation equipments in specific markets.

Can provide your local customers with after-sales service in time.

Founded in

Factory area

R & D Team

Fanty supports his distributors with co-branding opportunities and advertising materials. We also provide an Exhibition design for you participating exhibitions and major industry events to boost brand visibility and drive customer interest in your region.

Fanty's pricing structure is competitive and designed to provide attractive margins to his resellers. We offer a flexible pricing metal stamping automation equipmens model based on volume and long-term partnership, ensuring that you can achieve sustainable profitability.

Yes, Fanty offers exclusive distribution rights in select regions, depending on market size, demand, and the distributor's commitment. Exclusive rights help our partners maintain market share and reduce competition.

For the different regions and countries, the annual sales range shall be from $200,000 to $1,000,000.

Automotive

Automotive stamping involves the use of Decoiler Straightener Feeder +mechanical presses and dies to transform sheet metal into various shapes and sizes with precision and accuracy.

Household

Typically involves the use of decoiler, straightener, feeder and lower tonnage punch presses to shape and form thinner gauge metals into specific designs and dimensions for use in various household appliances.

Hardware

Normally involves the use of double hand decoiler, S loop Straightener, NC servo Feeder and presses to form and cut metal sheets into various shapes and sizes for use. Such as nuts, terminals, spring clips, and other small metal components.

Clothing

Clothing part stamping typically involves the use of flat decoiler and smaller punch presses to cut and shape metal components, such as buttons, rivets, and clasps, that are used in the manufacturing of clothing and accessories.