Cut-to-Length Line Solution of 1300mm Coil width

Specification:

| Model | GL-1300F NCF-1300F |

| Coil Width | 300-1300mm |

| Coil Loading weight | 10,000 kg |

| Maximum Outer Diameter | φ 1500mm |

| Hydraulic Expansion Range | Φ 460- Φ 520 mm |

| Customized | Yes |

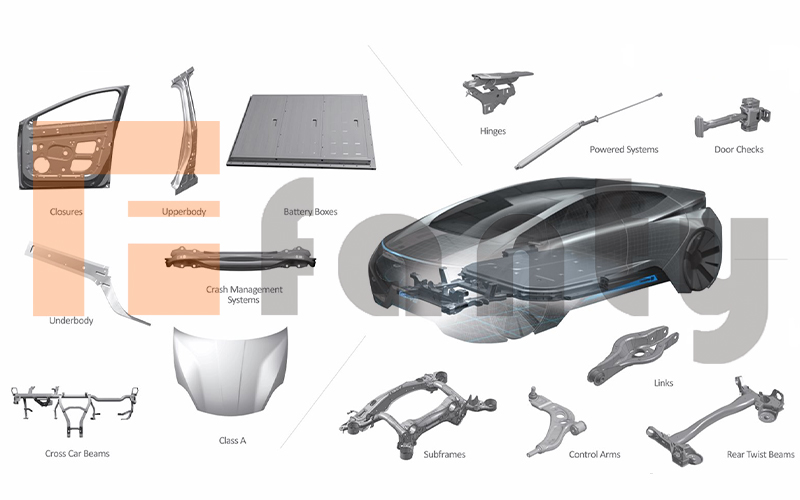

Our metal stamping solutions have been applied across various industries, catering to a diverse range of products and manufacturing requirements. By addressing complex stamping challenges with precision and efficiency, we have helped our customers streamline production, reduce downtime, and enhance overall quality. Each case is carefully designed to meet the specific needs of different sectors, ensuring optimal performance and long-term reliability. Explore the success stories below to see how our expertise has contributed to improved operations and greater productivity for our clients.

Learn about Coil-fed Laser Blanking Line.

Coil weight: MAX. 25T

Material thickness: 0.4~4.0 mm

Material width: MAX. 2000mm

Cutting speed: 0-120m/min (continuously variable)

Shearing burr: ≤thickness*3%

Shearing straightness: ≤0.1mm

Swing angle: ±35°

Threading speed: 0-15m/min

Cutting accuracy: 0.05mm~0.15mm

Swing accuracy:±3

Material: Galvanized plate/Cold rolled

steel plate/Color coated plate

Production capacity: 50000T/Year

| Model | GL-1300F NCF-1300F |

| Coil Width | 300-1300mm |

| Coil Loading weight | 10,000 kg |

| Maximum Outer Diameter | φ 1500mm |

| Hydraulic Expansion Range | Φ 460- Φ 520 mm |

| Customized | Yes |

Suitable Material: Stainless steel/Galvanized plate/Hot and cold rolled steel plate/Color coated plate

Coil weight: MAX. 25T

Material thickness: 0.3~3 mm

Material width:MAX. 2000mm

Production speed :200m/min

Width accuracy :0.05mm~0.15mm

Tensile strength:MAX 1480Mpa

Production capacity : 50000T/Year

| Model | MT-500 |

| Coil Width (mm) | 500 |

| Coil Thickness (mm) | 0.35~1.6mm |

| Coil Weight (kg) | 2500 |

| Feeding Speed (m/min) | 16 |

| Coil I.D. | 480~520mm |

| Coil O.D. | 1,200mm |

| Mandrer Expansion | Manual Expansion |

| Inverter Adjustment | With |

| Model | HP-30 |

| Master Cylinder Nominal Force | 300KN |

| Work Table Size | 800*350 mm |

| Moveable Beam Plate Cylinder Stroke | 150 mm |

| Die Height | 400 mm |

| Moveable Beam Plate Up of Down Speed | 100 mm/s |

| Working Speed of Moveable Beam | 10~20 mm/s |

| Rise Rate of Moveable Beam | 110 mm/s |

| Motor | 5.5KW |

| Max. Working Pressure | 400mm |

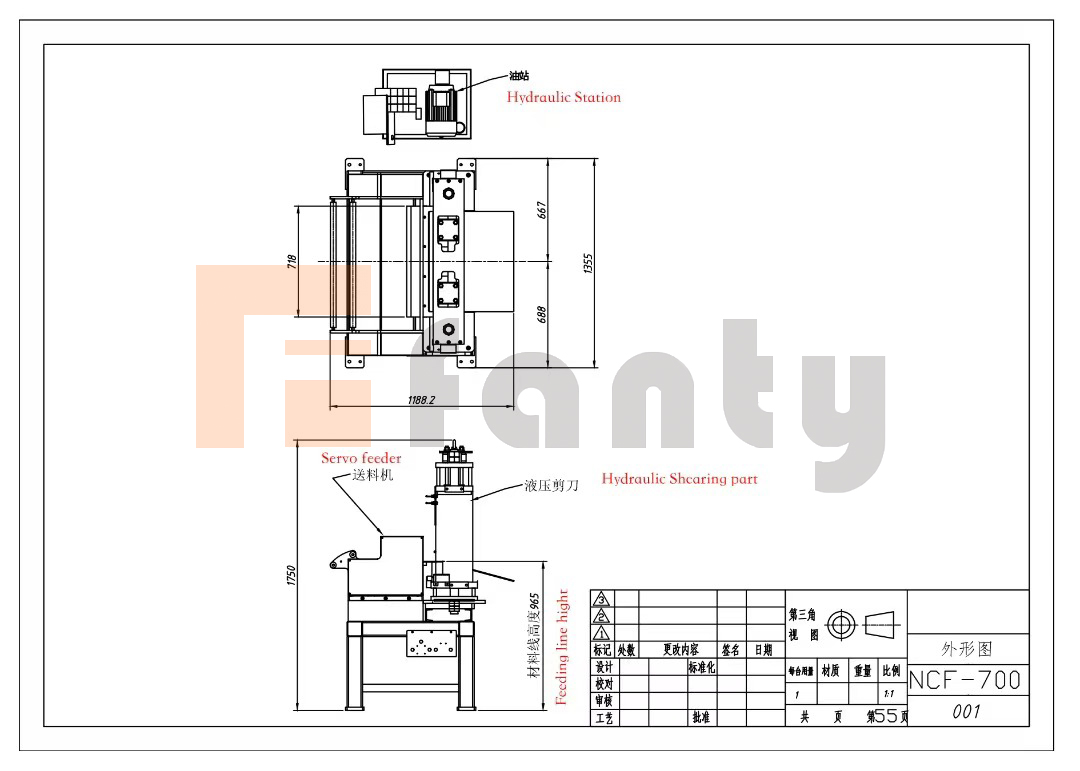

| Model | NCF-500 |

| Coil Width (mm) | 500 |

| Coil Thickness (mm) | 0.2~3.2mm |

| Feeding Length(mm) | 0~9999.99 |

| Feeding Speed (m/min) | 20 |

| Release Type | Pnumetic |

| Feeding Roller | 2 pcs |

| Touch Screen | Weinview |

| PLC | Mitsubishi |

| Servo Motor | Mitsubishi |

| Model | MT-500F |

| Coil Width (mm) | 500 |

| Coil Thickness (mm) | 0.35~1.6mm |

| Coil Weight (kg) | 2500 |

| Feeding Speed (m/min) | 16 |

| Coil I.D. | 200~300 mm |

| Coil O.D. | 1,200 mm |

| Mandrer Expansion | Manual Expansion |

| Inverter Adjustment | With |

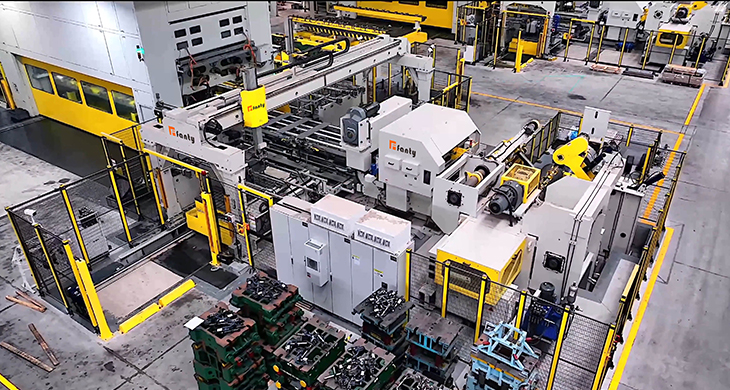

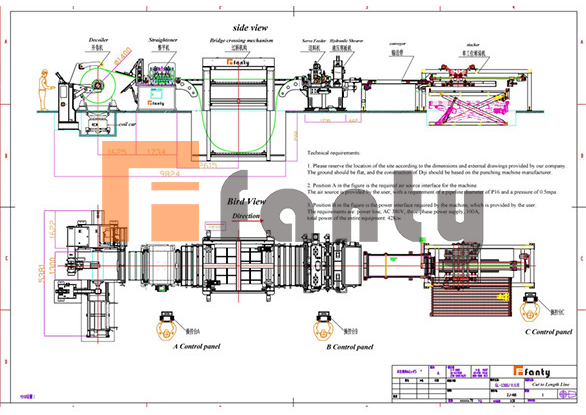

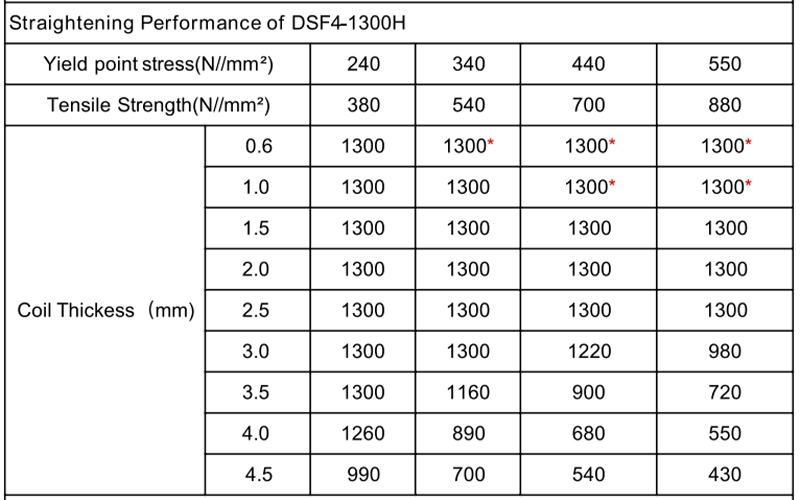

Fanty DSF Series Decoiler Straightener Feeder Machine combines three essential functions – decoiling, straightening, and feeding – into a single unit, effectively eliminating manual handling, reducing setup time, and enhancing overall production efficiency. It works as a perfect metal stamping automation equipments for auto parts production. The model DSF4-1300H is applied in this case for our customer in Romania

Quick Quote !

| Model | DSF4-1300H |

| Applicable Material | SPCC,SECC, High Strength Steel |

| Material Strength | Yield Strength Less 550; Tensile Strength Less 880 |

| Sutiable Coil Width | 130~1300mm |

| Sutiable Coil Thickness | 0.6~4.5mm |

| Coil I.D. | 508 |

| Coil O.D. | 700~1,500 |

| Coil Loading Weight | 1,5000kgs |

| Coil Running Direcction | Right to Left |

| Coil Car | Hydraulic Type |

| Expansion Way | Hydraulic Expansion |

| Uncoiler Drive | AC Motor with Frequency Converter |

| Material Arc Control | Photoelectric |

| Pressuring Arm | Air Pressuring with Electric Pressuring Wheel |

| Spindle Support Arm | Yes |

| Coil O.D. | 1,200 |

| Mandrer Expansion | Manual Expansion |

| Model | MT-700 |

| Applicable Material | SPCC,SECC, High Strength Steel |

| Material Strength | Yield Strength Less 550; Tensile Strength Less 880 |

| Sutiable Coil Width | 700mm |

| Sutiable Coil Thickness | 0.1~2.2mm |

| Coil I.D. | Ø450-530mm |

| Coil O.D. | Ø1200mm |

| Coil Loading Weight | 2,000kgs |

| Coil Width | 700mm |

| Coil Thickness | 0.1~2.2mm |

| Servo Motor | Mitsubishi |

| Coil Width | 700mm |

| Coil Thickness | 0.1~0.8mm |

| Speed | 18times/min |

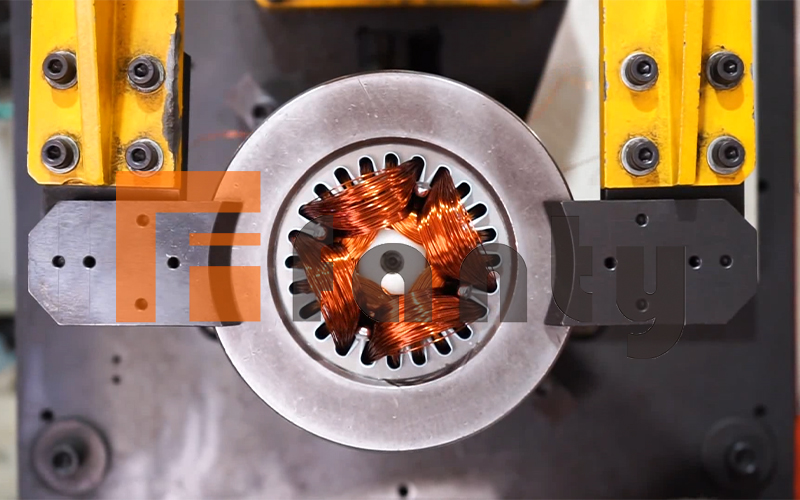

| Model | APA-45 |

| Capacity | 45 tons |

| Rated Tonnage Point (mm) | 1.6 mm |

| Stroke Per Minute(s.p.m) | 80~120(s.p.m) |

| Stroke(mm) | 45mm |

| Min. Die Height(mm) | 177(mm) |

| Max. Die Height(mm) | 232 mm |

| Slide Adjustment (mm) | 55(mm) |

| Model | DBMT-500 NCF-500B |

| Coil Thickness | 0.2mm-1.2mm |

| Coil Width | 500mm(MAX) |

| Feeding Pitch | 60m/min |

| Bloster Size | 2300mm×1000mm(L×W) |

| Bed Opening | 1900mm×300mm |

Founded in

Factory area

R&D Team