- Production

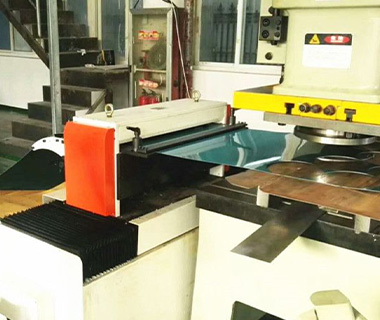

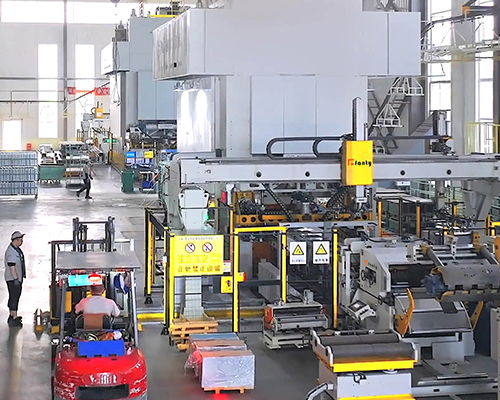

High - volume production: demands a coil press blanking line with high speed capabilities. Consider lines with rapid uncoiling, fast feeding, and quick - acting presses.

Low - volume production: may be better served by a more cost effective assisted line.

- Material

Type: Different materials, such as steel, aluminum, copper, or various alloys, have distinct properties that affect the blanking process.

Thickness: Thickness of the material determines the force required. Thicker coils need presses with higher tonnage.

- Compatibility

Compatibility with Existing Equipment: If you already have other machinery in your production line, such as stamping machines, welding equipment, or conveyor systems, ensure that the coil press blanking line you choose is compatible.

- Budget

Operating costs: include energy consumption, lubricants, and the cost of replacement parts.

Maintenance costs: regular maintenance is necessary to keep the line running smoothly and prevent breakdowns.