Reason 1

Automation Needs

Seeking to improve metal stamping production efficiency, reduce manual operations, and enhance automation in production lines.

Seeking to improve metal stamping production efficiency, reduce manual operations, and enhance automation in production lines.

Unique metal stamping product shapes, sizes, or materials that standard metal coil processing equipment cannot handle.

Looking to optimize existing metal stamping production lines to reduce downtime, increase capacity, and improve flexibility.

Limited factory space that need metal coil processing equipment customized to fit existing layout.

Need high precision and consistency for metal stamping products with stringent quality standards.

Need flexible production lines capable of handling small batches and multiple metal stamping product types.

Work with new, hard-to-process metal materials or requiring customized metal coil processing equipment for specific characteristics

To Solve These Above, Are You Trying To Find A Manufacturer Who Can Supply Certain Metal Coil Processing Equipment For Your Stamping Line ?

Start with a detailed outline of needs: material specifications (e.g., thickness, width, type), desired processing steps (decoiling, straightening, feeding), automation level, precision, and production speed. This helps narrow down providers specializing in custom equipment for those exact requirements.

Look for manufacturers with a strong industry presence and a track record in metal coil processing equipment. Check if they offer both standard and custom solutions and are experienced with similar projects.

Choose companies with engineering expertise in metal coil processing and stamping automation solutions. Review their portfolio, case studies, and the technical support they provide to understand their customization capabilities.

Strong after-sales support is crucial for custom metal coil processing equipment. Confirm the provider offers installation guidance, maintenance services, technical support, and readily available spare parts.

Engage potential suppliers by requesting initial consultations. Discuss your specific customization needs, and evaluate their responsiveness and design capabilities. Reliable providers will offer suggestions, customization options, and even CAD designs to ensure alignment with your needs.

Reliable providers often hold industry-standard certifications (e.g., ISO 9001) that ensure high-quality production standards. Check if they adhere to relevant safety and quality norms for your industry.

As a professional metal coil processing equipment manufacturer, Fanty provides perfect-matching OEM/ODM service for you, we will work with you to design and manufacture a metal stamping automation equipment that meets your specific needs, such as suit for your coil specification( e.g., thickness, width, type and weight), precision, and production speed. The equipment will then be manufactured in accordance with your requests, with your branding and labeling, and distributed to you or your clients.

1

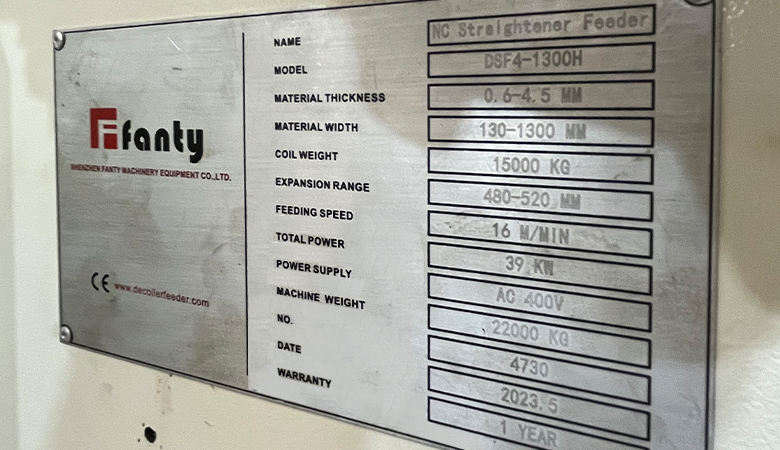

1The coil processing equipment normally have the label applied to them during manufacture.

Label customization is the process of imprinting the equipment with the name and logo of the business in charge of custom creation. You can have your company name, logo and any other identifying information you want to include on the equpment.

You can collaborate with Fanty's designers to build a unique design that meets your requirements or you can supply artwork or graphic files that incorporate your branding.

2

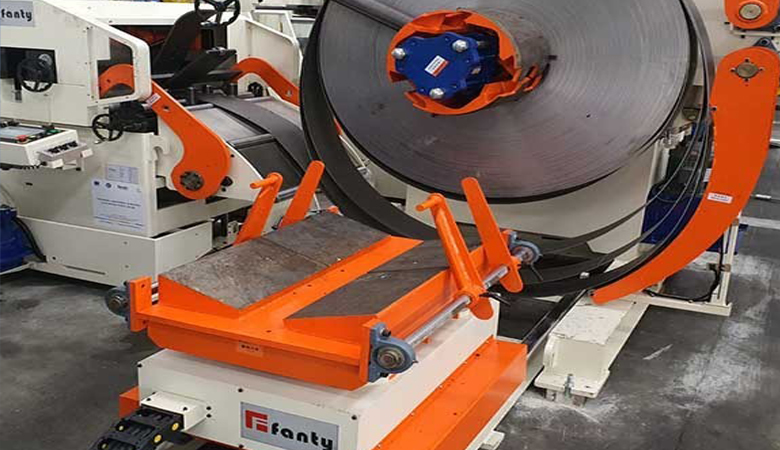

2Core Shaft Expansion: Manual or Hydraulic Expansion

Coil Cars: provide custom-designed coil cars to support the safe and efficient transportation of coils within your facility.

Cutting effect: Test with tablets of different hardness and size to ensure that the tablets can be cut evenly.

Pressing Arms: Our pressing arms are designed to enhance the handling and leveling process of coils, offering precise control and improving overall efficiency during the feeding and processing stages.

3

3Develop new functional modules or add new design requirements for customers based on existing technologies. Such as adding "Hydraulic shearer" parts on our current NC Servo Feeder for our customer in U.A.E etc.

4

4According to customer requirements, parameters, drawings, we discuss with customers, together, and make complete ODM design on our existing machines.

Clarify the functional requirements of customized equipment and clarify the technical parameters of the equipment.

Customized services usually involve additional costs. Customers need to confirm the budget and discuss the cost structure with suppliers to avoid unexpected costs later.

Customized equipment may require a longer production cycle, so it is necessary to confirm the delivery time with the supplier to avoid affecting the production plan.

1. Get your demands

2. Coil Material Information

1. Confirm the design draft details

2. Give technical advice

3. Confirm the final design

Provide a detailed quotation including price, specifications, warranty, delivery time, payment terms, package type and layout (if it is a decoiler straightener/decoiler straightener feeder).

Get the PO (Purchase Order) from customer after quotation is confirmed.

Sign PI (Proforma Invoice)

1. Arrange the equipment production;

2. In-line quality inspection;

3. Control the lead time.

Carry out a equipment running test in accordance with clients' specifications

Deliver on time

Assist in resolving after-sales issues

Yes, we offer comprehensive OEM/ODM services. Based on your production requirements and technical specifications, we can design and manufacture coil processing equipment that meets your exact needs. Whether it's for equipment functions, dimensions, materials, or specific features, we can customize according to your requirements.

The delivery time for custom coil processing equipment depends on the complexity of the design and the customization requirements. We will provide a detailed timeline based on your specific needs. We will confirm the delivery schedule with you upfront and ensure that the equipment is delivered on time.

The price of custom a coil processing equipment typically depends on factors such as design complexity, selected materials, functional requirements, and order quantity. After receiving your detailed requirements, we will provide an accurate quote. We ensure transparent pricing to avoid any hidden fees.

Yes, all Fanty custom coil processing equipment is designed and manufactured according to international safety standards and quality control processes. We ensure that the equipment complies with relevant industry safety standards, such as ISO certification, and undergoes rigorous quality inspections to guarantee stability and safety during operation.

Fanty provides comprehensive after-sales service for all custom coil processing equipment, including installation, commissioning, and operator training. If any issues arise during operation, our professional team offers timely remote or on-site support. The equipment is also covered by a year warranty, and we offer long-term maintenance services.

Yes, Fanty offers full maintenance support for custom coil processing equipment, including regular inspections, technical support, and spare parts supply. We provide maintenance recommendations based on the equipment’s usage and ensure that you can easily access the required spare parts to minimize downtime.

FANTY provides custom solutions to your metal coil processing and stamping automation.

Fanty coil processing equipment manufacture covers: uncoiler/decoilre machines, press feeders, punch press, transfer etc.

Fanty supply a high quality metal coil processing equipments to improve your metal stamping efficiency and save your cost.