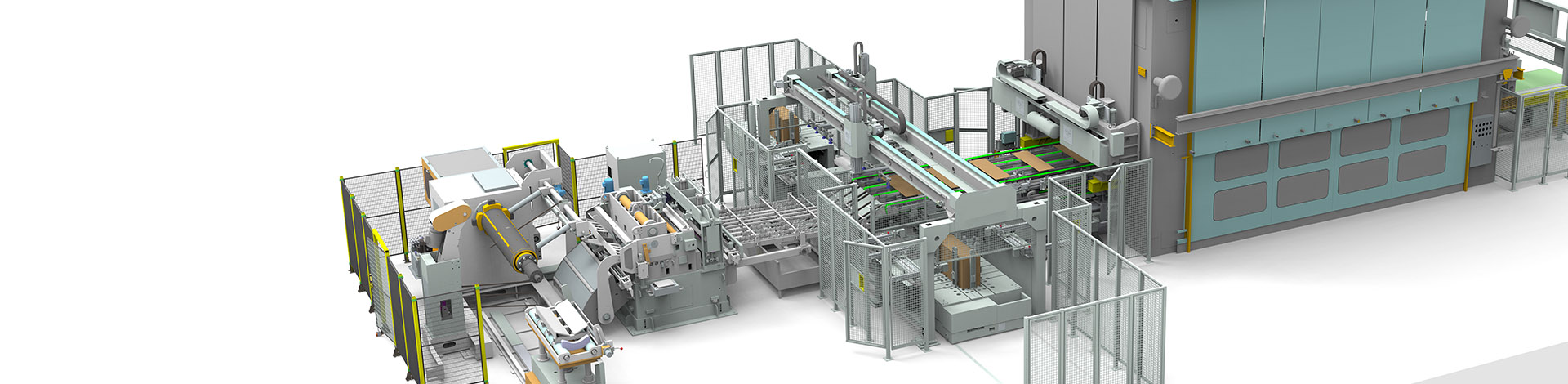

Low production efficiency

Traditional production lines often rely on manual or semi-automatic transfer of workpieces between different stamping or processing stations. This results in significant time wasted during handling and positioning, leading to slow production cycles.

Inconsistent product quality

Manual handling of workpieces is prone to human error, such as misalignment during stamping operations. Even a slight deviation in positioning can lead to defective products. For instance, in the production of washing machine inner drums, inaccurate placement during the stamping process can result in uneven walls or improper fitting of components

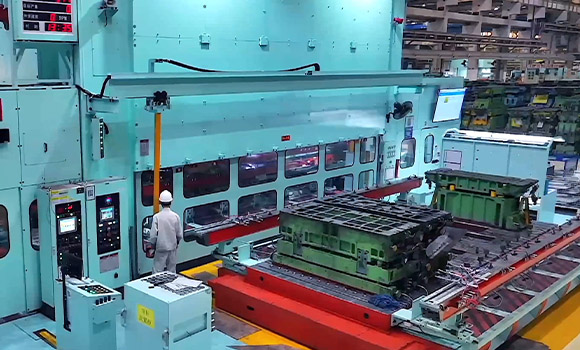

High labor costs

Manual labor is required for tasks such as workpiece transfer, positioning, and quality inspection in traditional home appliance manufacturing processes. As labor costs continue to rise, especially in regions with high labor standards, this becomes a significant burden for manufacturers.

Limited production flexibility

Home appliance manufacturers often need to produce a wide variety of products to meet market demands. Traditional production setups may be rigid and difficult to adapt quickly to new product designs or specifications.

Difficulty in quality traceability

In the complex manufacturing process of home appliances, it can be challenging to track the origin and processing history of each component. In case of quality issues, it becomes difficult to identify the root cause and take corrective actions.

Equipment reliability and maintenance

Some traditional transfer equipment may be prone to breakdowns due to wear and tear or complex mechanical structures. Frequent equipment failures can lead to production downtime and increased maintenance costs.