R & D Capabilities

80+ R&D teams with more than 15+ years of experience.

80+ R&D teams with more than 15+ years of experience.

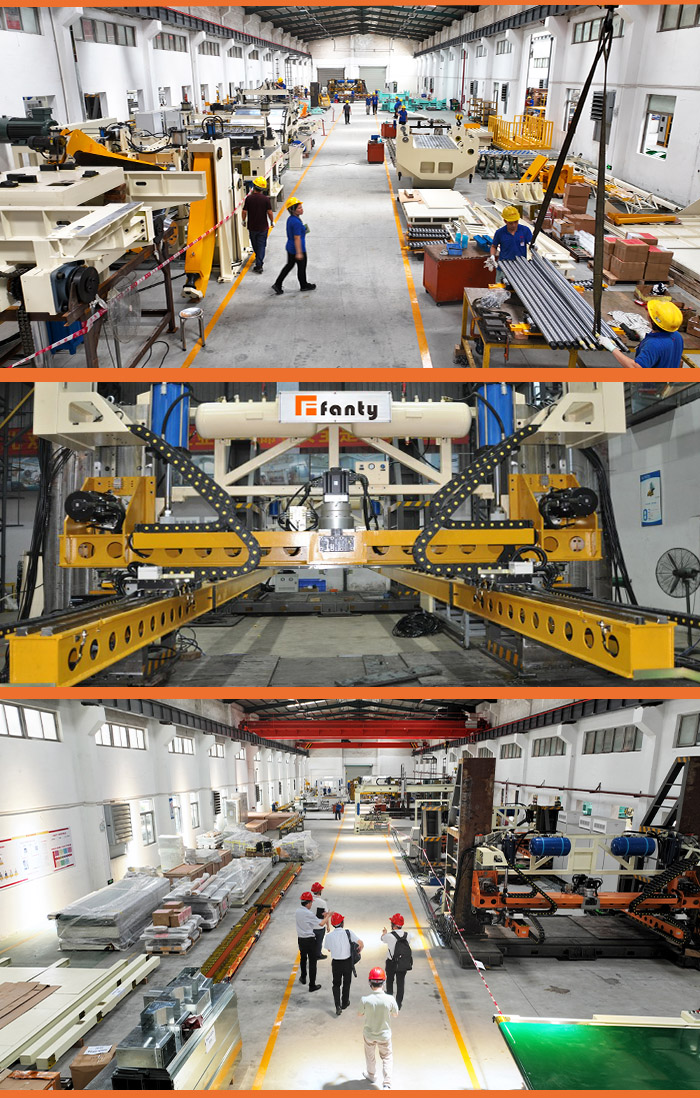

More than 45,000 square meters of modern factory

Make our efforts for a sustainable future

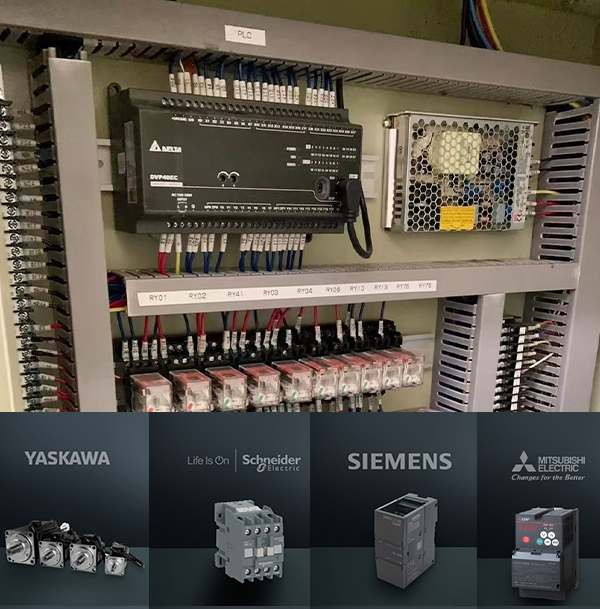

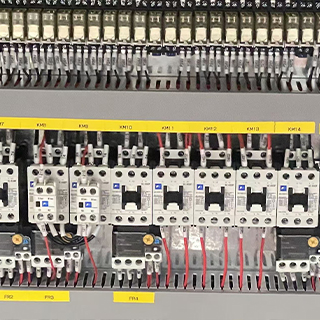

Choose a reputable PLC's electronics brands to ensure the source of raw materials is reliable.

PLC's electronic parts purchasing like: Server Driver, Circuit breaker, Contactor, Relay, Pneumatic element, Photoelectric induction, Cylinder for release and feeding, Inverter etc. are from Delta,Yaskawa, Mitsubishi, Fuji, Schneider, Izumi, Omron, SMC, NSK, NTN etc famous brands. Each batch of electronic parts must be strictly tested before entering the factory, including:

1. Appearance inspection to see if there are any abnormalities such as cracks, deformation, oxidation, discoloration, etc.

2. Functional inspection: Check whether the components meet the specification requirements by conducting electrical performance tests on electronic components, such as the capacity of capacitors and the resistance of resistors.

3. Withstand voltage test: Check whether the withstand voltage performance of components meets the specification requirements by conducting high voltage tests on electronic components.

Choose a reputable metal/steel supplier and regularly review its qualifications and quality management system to ensure that the source of raw materials is reliable.

Each steel/metal raw materials must be strictly tested before entering the factory, including Including dimensions, size, weight, chemical composition, mechanical strength, heat treatment status, test results, traceability, etc.

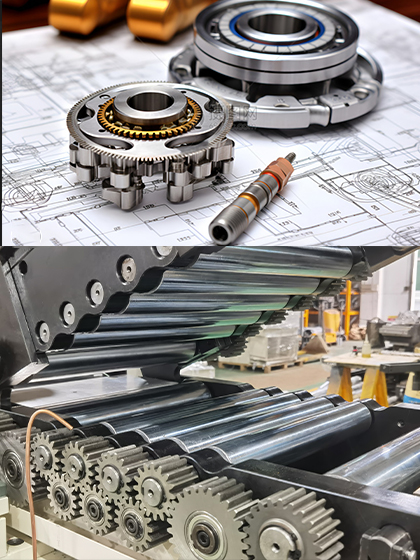

At Fanty, Research & Development and Manufacturing integration of core technology is one of the advantages of our value chain.

Drawing and design of high-precision hardware can ensure the safety of customers using metal stamping automation equipments.

Reasonable design of metal stamping automation equipments can ensure efficient coil process and reduce customer investment costs.

Providing custom metal stamping lines design to meets our customers different needs to coil processing and metal stamping.

More than 20 patents certificate as a manufacturer with ISO9001.

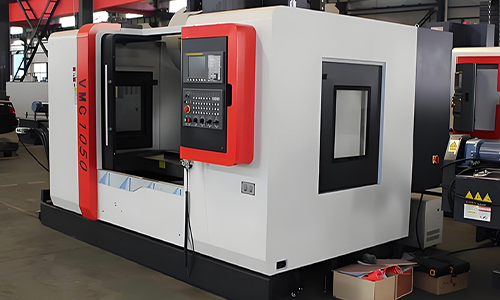

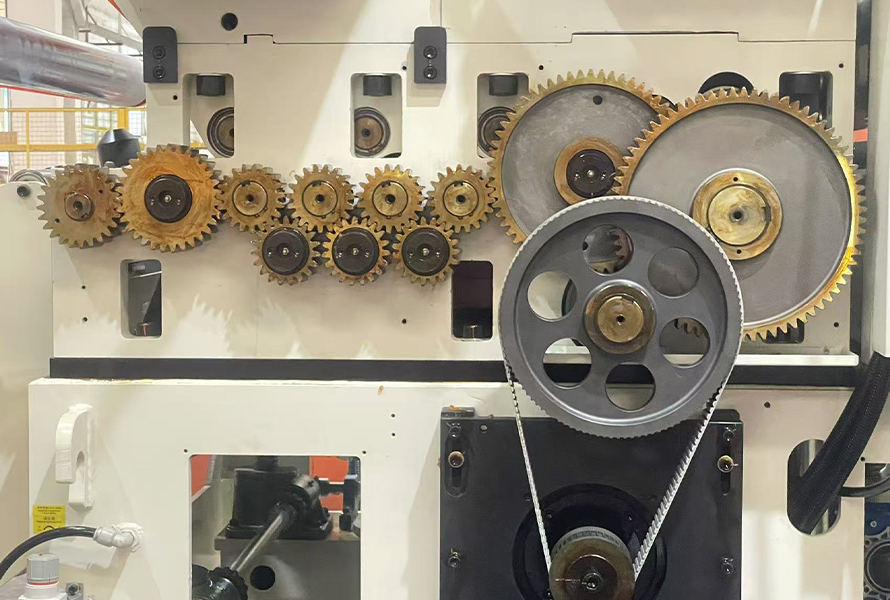

Processing the cylinder to guarantee the size and appearance of hardware parts.

Process like milling, boring, drilling, hole enlarging, countersinking, etc.

Light and heavy cutting, able to meet the high-speed and high-precision milling processing needs.

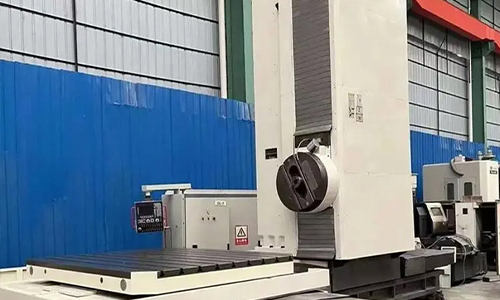

Process accessories for unwinding equipment with high precision and flatness

Process the outer cylindrical surfaces, conical surfaces, spherical surfaces and threads of machining accessories.

Process the internal and external rotating surfaces, end faces and internal and external threads of various hardware parts.

Cutting coil handling equipments' raw material like low carbon steel, stainless steel etc.

Used for various processing such as drilling, reaming, tapping and scraping end faces

Provide assembly line for uncoilers/decoiler machines. Such as flat decoiler, manual decoiler, hydraulic decoiler,double head decoiler...

Uncoiler/Decoiler

Provide assembly line for NC Servo Feeder, Roll Feeder, Gripper Feeder, Zigzag Feeder.

Press Feeder

Provide assembly line for decoiler straightener machines and also for Transfer products.

Decoiler Straightener

Provide assembly line for decoiler straightener feeder machines.

Decoiler Straightener Feeder

Check the appearance of the metal stamping automation equipmens to see if there are any silk-screen marking errors, scratches, and whether the equipment is clean, etc.

Check whether the voltage, logo, nameplate, and parameters are consistent with customer requirements

Check if there is any scratch on the hardware parts. Make sure the safety during customers' use.

Check if the voltage, electronics brands and frequency meet the customer requirement.

Check if the wires are connected in right way. Make sure the safety when customer's first operation.

Run the equipment and make sure every control operation is smooth make sure customer operate smoothly also after receive the equipment.

Small equipment is packaged in a wooden case. Big equipment shall be covered with waterproof material and loaded into the container and secured with ropes.

A: The normal decoiler machines & press feeders delivery period after the customer places an order is 10 days. Decoiler Straightener & Decoiler Straightener Feeder need 30days roughly. Customized Equipments shall depend on the detailed equipments requirement. Special circumstances will be communicated in advance.For more information, please kindly contact us.

A: Fanty specializes in developing and producing high-quality metal stamping automation equipments designed to help our customers reduce costs without compromising on quality. In today’s market, we know customers face many choices, including a surge of low-cost equipment options that often come with hidden issues—cheap inverters, flimsy rollers, and unnamed servo motors can quickly lead to costly downtime and frustration. At Fanty, we stand apart by upholding high standards in integrity, quality, and reliability because we know these values earn long-term trust and satisfaction.

A: 1, Coil material.

2, Material thickness (mm).

3, Material Width(mm).

4, Material Weight (kgs).

5, What's the coil thickness when it is at its max width?

6, What's the coil width when it is at its max thickness?

7, More details, pls email us sales@sz-fanty.com

A: 1, For the different regions and countries, the annual sales range shall be from $200,000 to $1,000,000. 2, Learn about steel coil handling equipments and can provide after-sales support locally. 3, Optimistic about the prospects of metal stamping automation equipments and metal stamping automation, and signed an agency contract with Fanty.

A: 1. Fanty metal stamping automation equipments have a year warranty. 2. There are professional after-sales personnel to help you solve equipments and technical problems.3. Can provide installation instructions for use and other documents.4. Free train at our factory.5. Visit customers any time for a support if problems cannot be solved remotely.

A: Sure. We warmly welcome your visit to our factory.

Over 10 years as a manufacturer of metal stamping automation equipments with 80+ R&D Team.

Provides various metal stamping automation solutions for our customer.

The pursuit of producing high-quality metal stamping automation equipments. Visit our Factory !