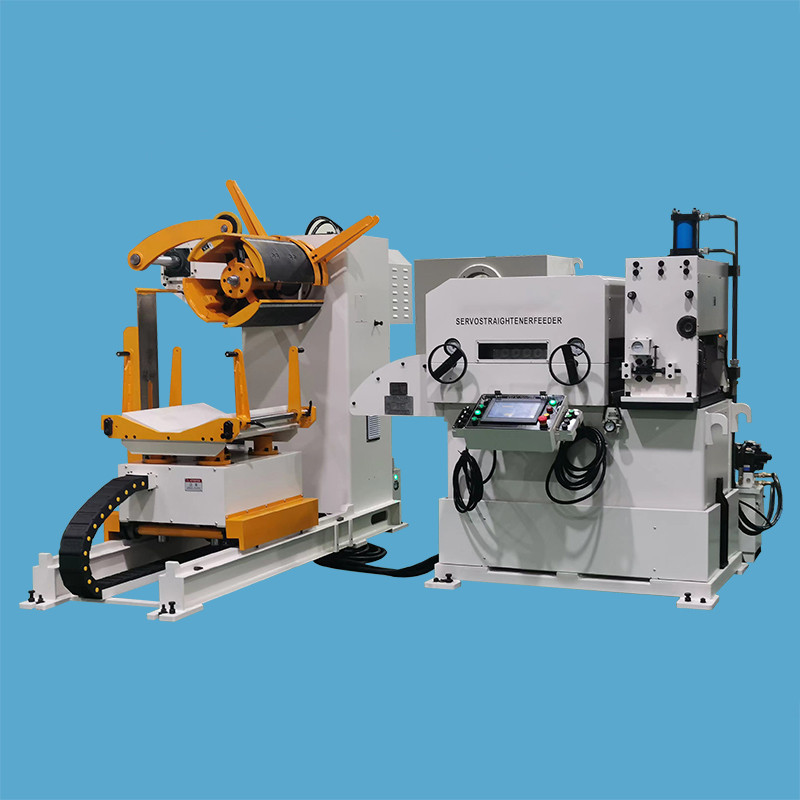

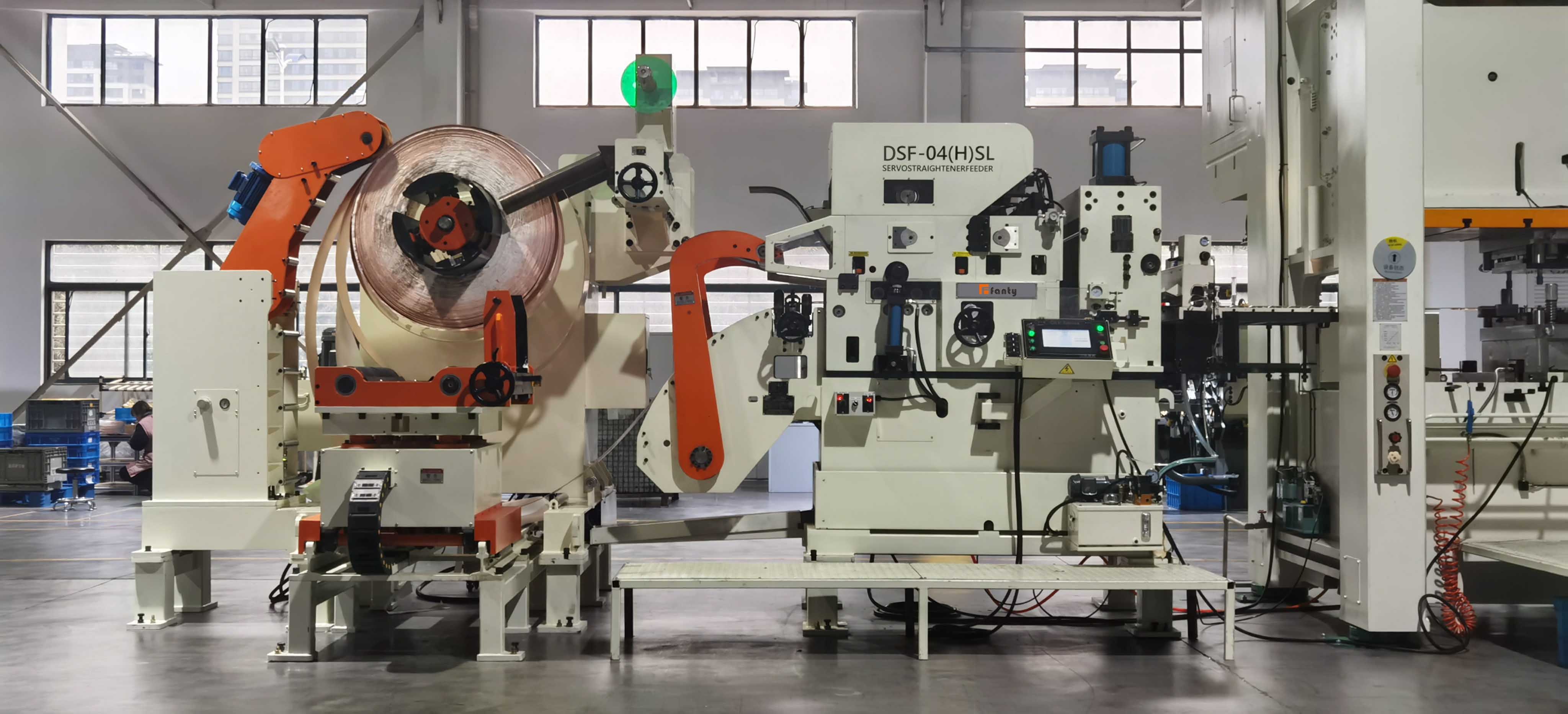

Decoiler Straightener Feeder

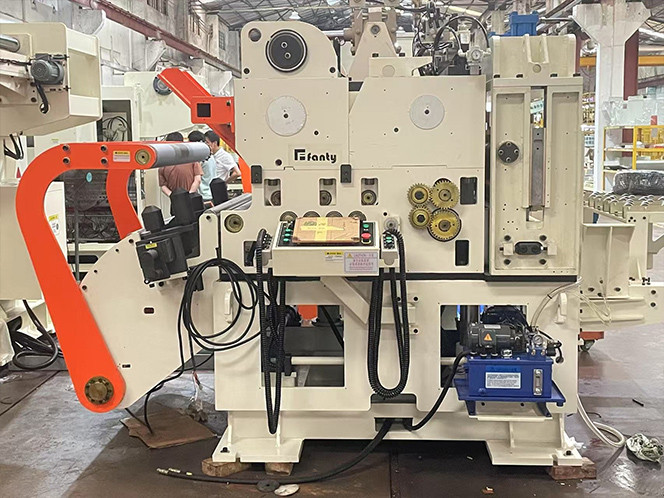

FANTY Decoiler Straightener Feeder is a metal stamping automation equipment, which is also called uncoiler straightener feeder or NC Straightener Feeder. This type steel coil handling equipment combines the advantages of a decoiler, straightener, and feeder into a single and efficient unit. It handles the unwinding of coil material, straightening it to precision, and accurately feeding it for further processing.

Introduction to Decoiler Straightener Feeder

To satisfy your unique needs, the FANTY decoiler straightener feeder is made to accommodate a wide variety of material width and thickness. It has been extensively employed in the furniture fitting, home appliance, and car part sectors. The decoiler straightener feeder machine promotes productivity and safety by operating quickly and with improved straightening capabilities. Its great economic use is embodied by qualities that save time, space, and labor.

A Decoiler Straightener Feeder machine is an equipment designed to process coil materials in the metal stamping production. It combines three essential functions – decoiling, straightening, and feeding – into a single unit, effectively eliminating manual handling, reducing setup time, and enhancing overall production efficiency, and save labor cost for sure.

How to process steel coil by the Decoiler Straightener Feeder

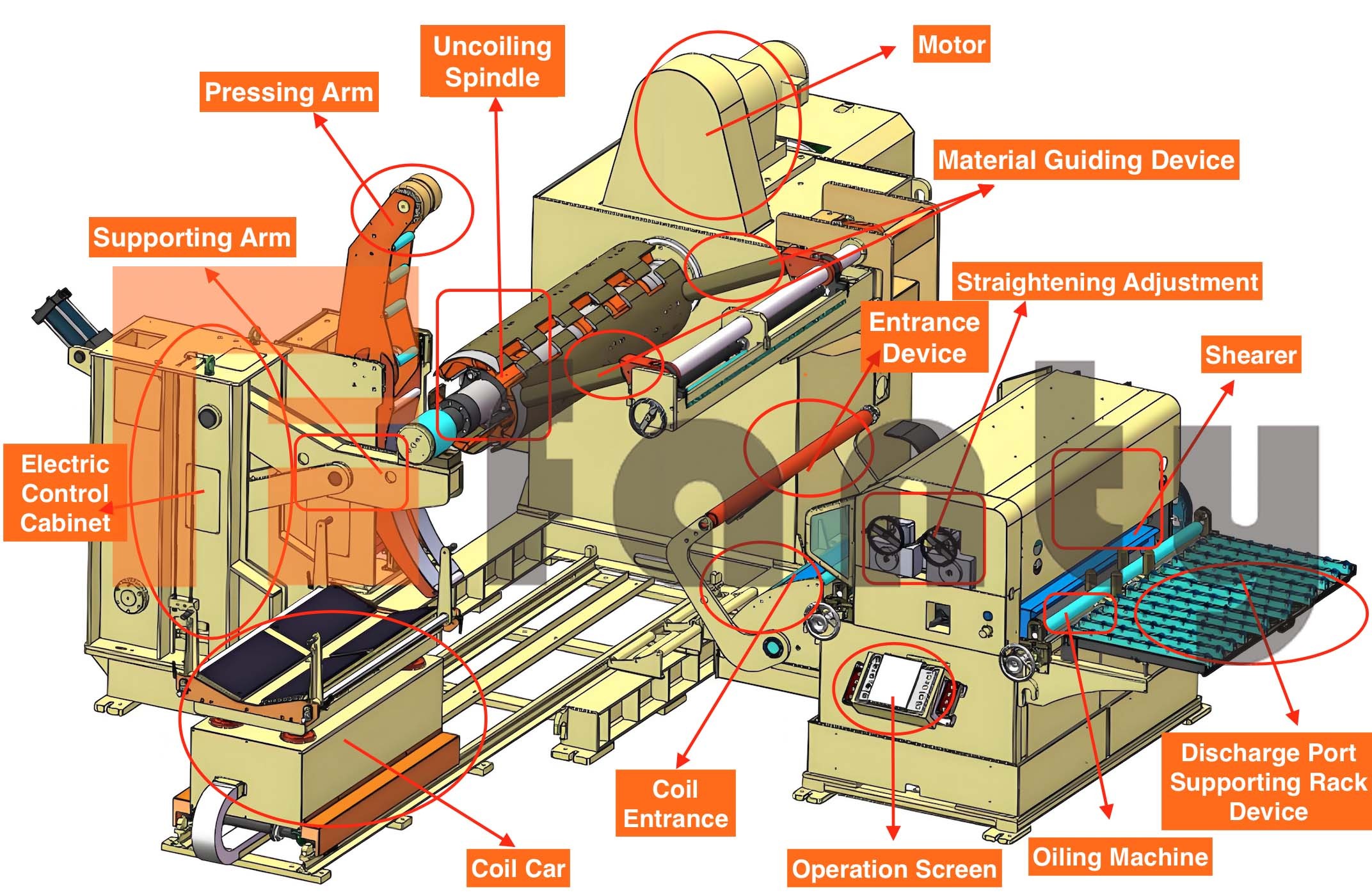

What is the structurer of Decoiler Straightener Feeder Machine?

Part Name | Function | Part Name | Function |

| ① Coil Car | For a safe loading to heavy coil | ⑦ Entrance Device | Electric adjust the distance |

| ② Supporting Arm | Prevent the coil from falling due to heavy weight | ⑧ Straightening Adjustment | Leveling amount adjustment |

| ③ Pressing Arm | Prevent the material roll from spreading during operation | ⑨ Operation Screen | Correction amount display |

| ④ Uncoiling Spindle | Hydraulic expansion; Uncoiling the coil | ⑩ Shearer | Shearing the head and tail of the coil material |

⑤ Motor | Spindle Drive Motor | ⑪ Oiling Machine | Oiling the surface of materials |

⑥ Material Guiding Device | Position the width of the coil | ⑫ Discharge Port Rack | Smooth transmission between the fixed size feeding and the mold |

1. The brief structurer

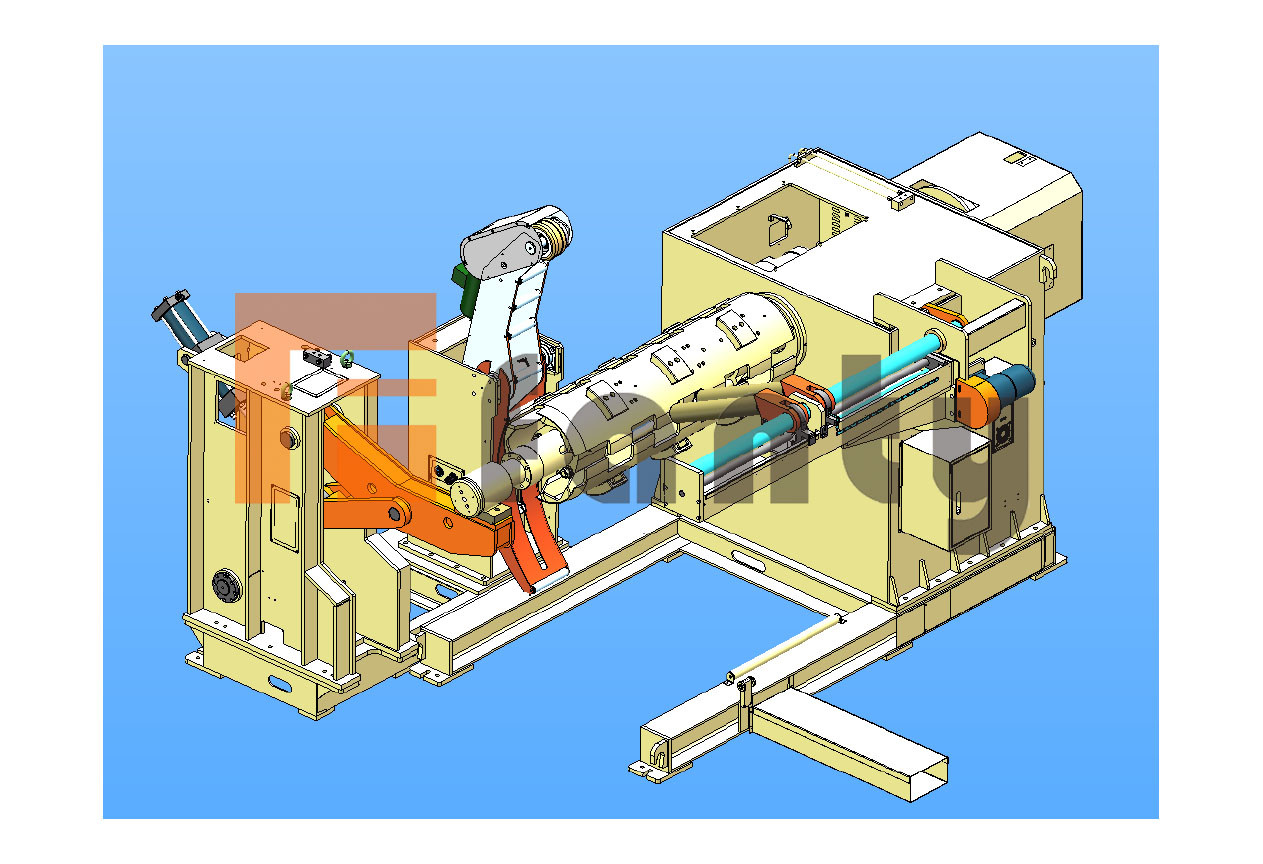

Decoiling Part

The machine's decoiling mechanism ensures the smooth and controlled unwinding of metal coils, preventing tangling or material distortion. This is crucial to maintain a consistent material feed throughout the production process.

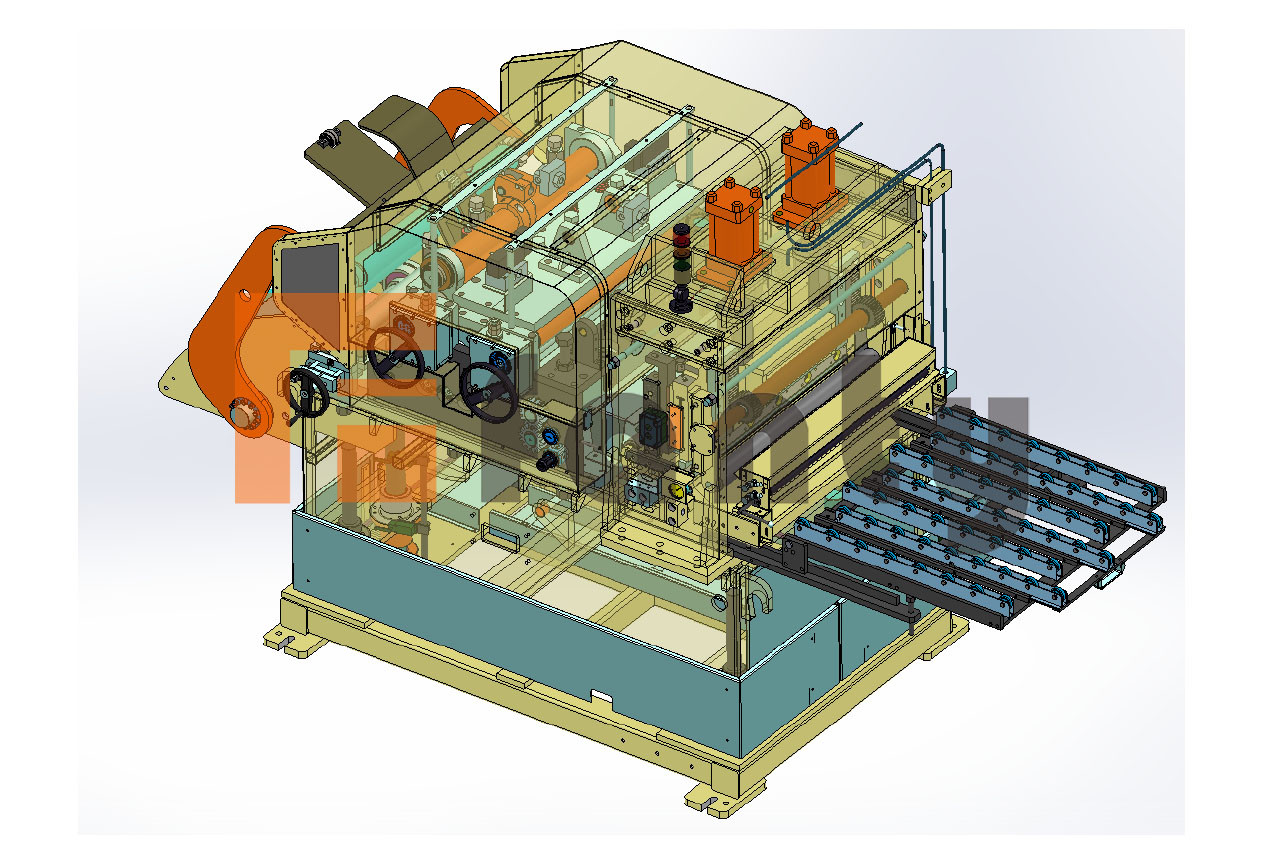

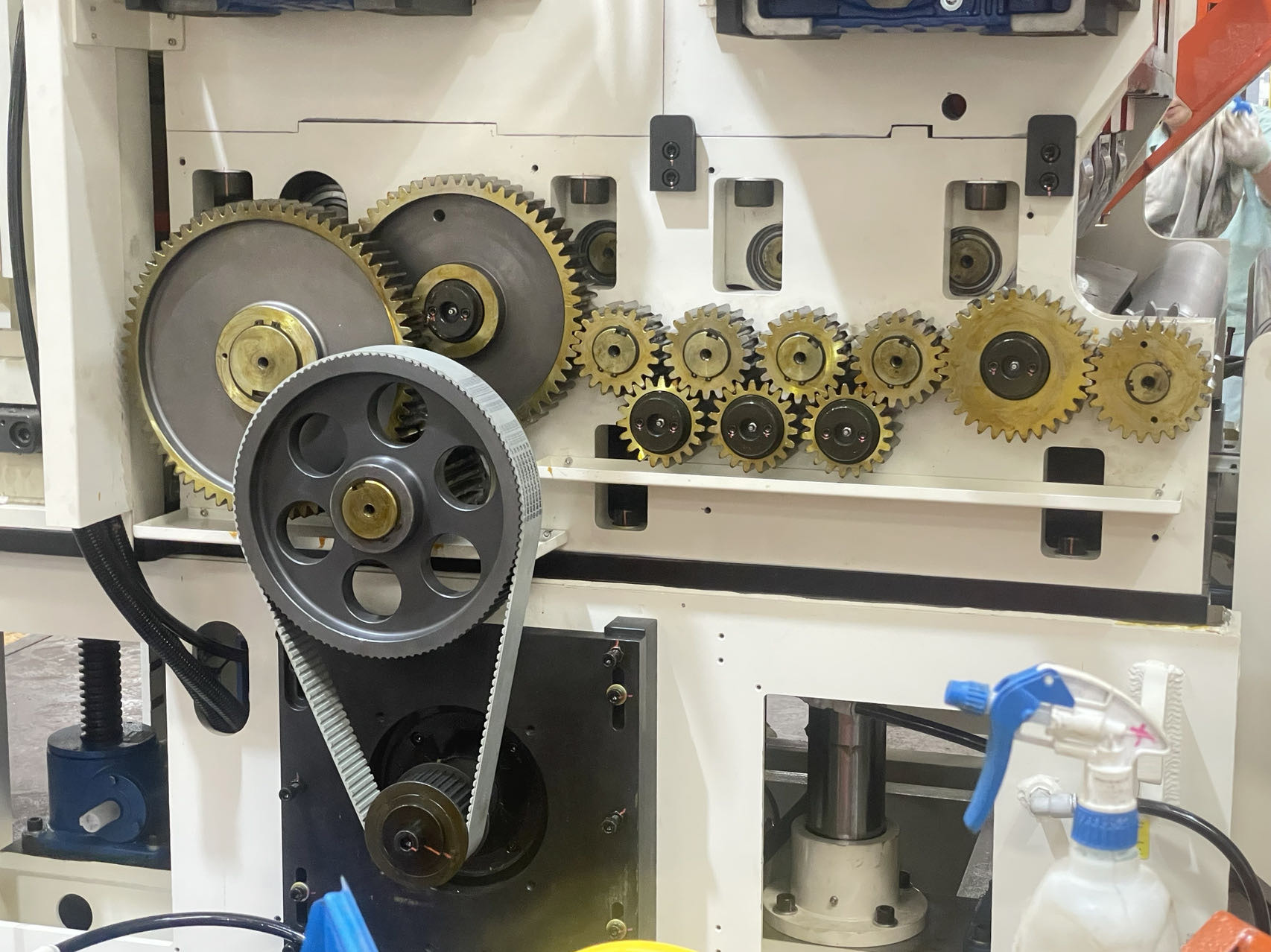

Straightening & Feeding Part

After coil decoiling, the straightening & feeding part is responsible for flattening and aligning the metal strip. The feeding function of the machine accurately delivers the straightened metal strip to downstream equipment, such as presses or stamping machines.

2. The optional structurer

Coiler Car

Move the material safely and smoothly to the expansion and contraction structure of the main shaft of the unwinding machine. For loading 3tons, 5tons, 8tons and 10 tons coil weight safely.

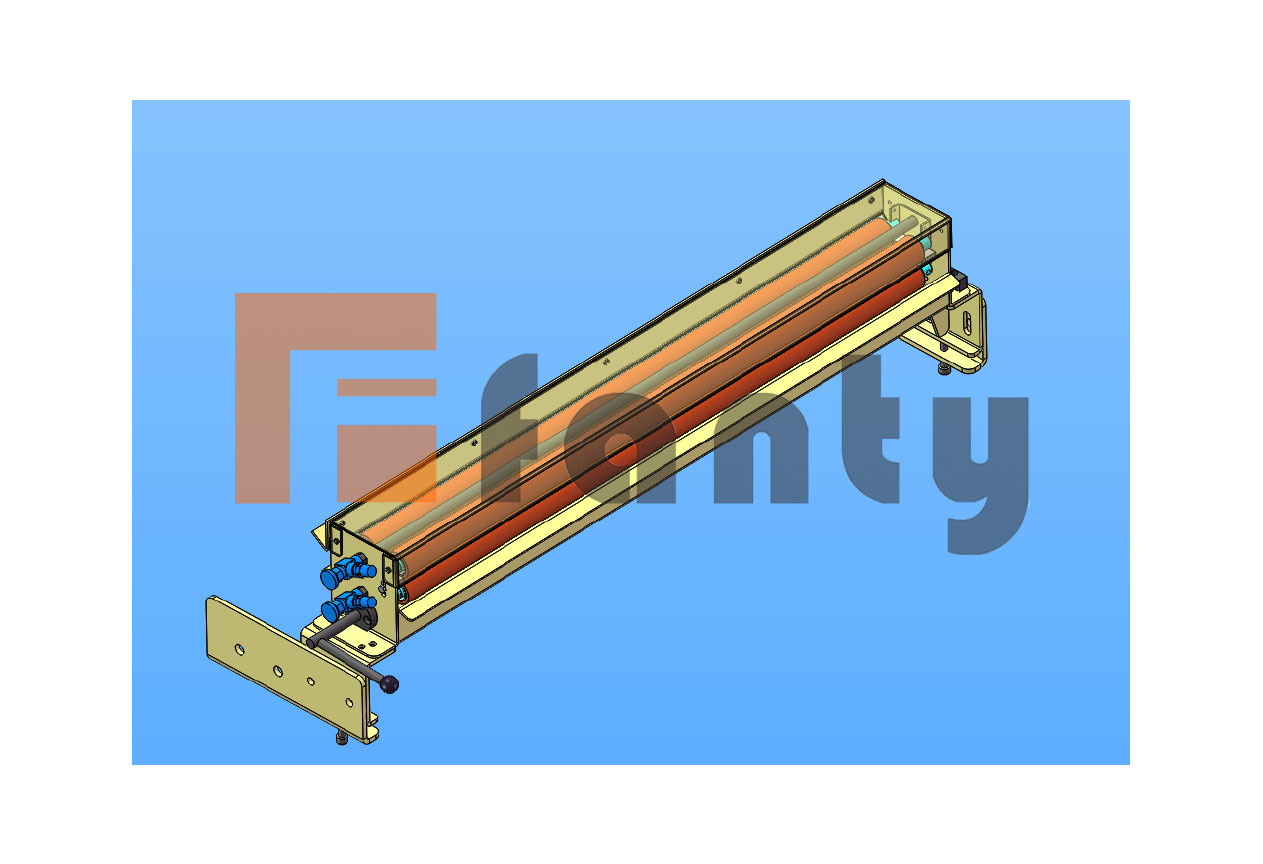

Hydraulic Shearer

Normally, it will be installed at the end of straightener feeder part for cutting coil into sheet. The Hydraulic Shearer is mainly used for shearing the head and tail of the material.

Electronic Oiling Machine

Used for oiling the surface of materials, and the oiling amount and oiling interval are electronically controlled and adjustable.

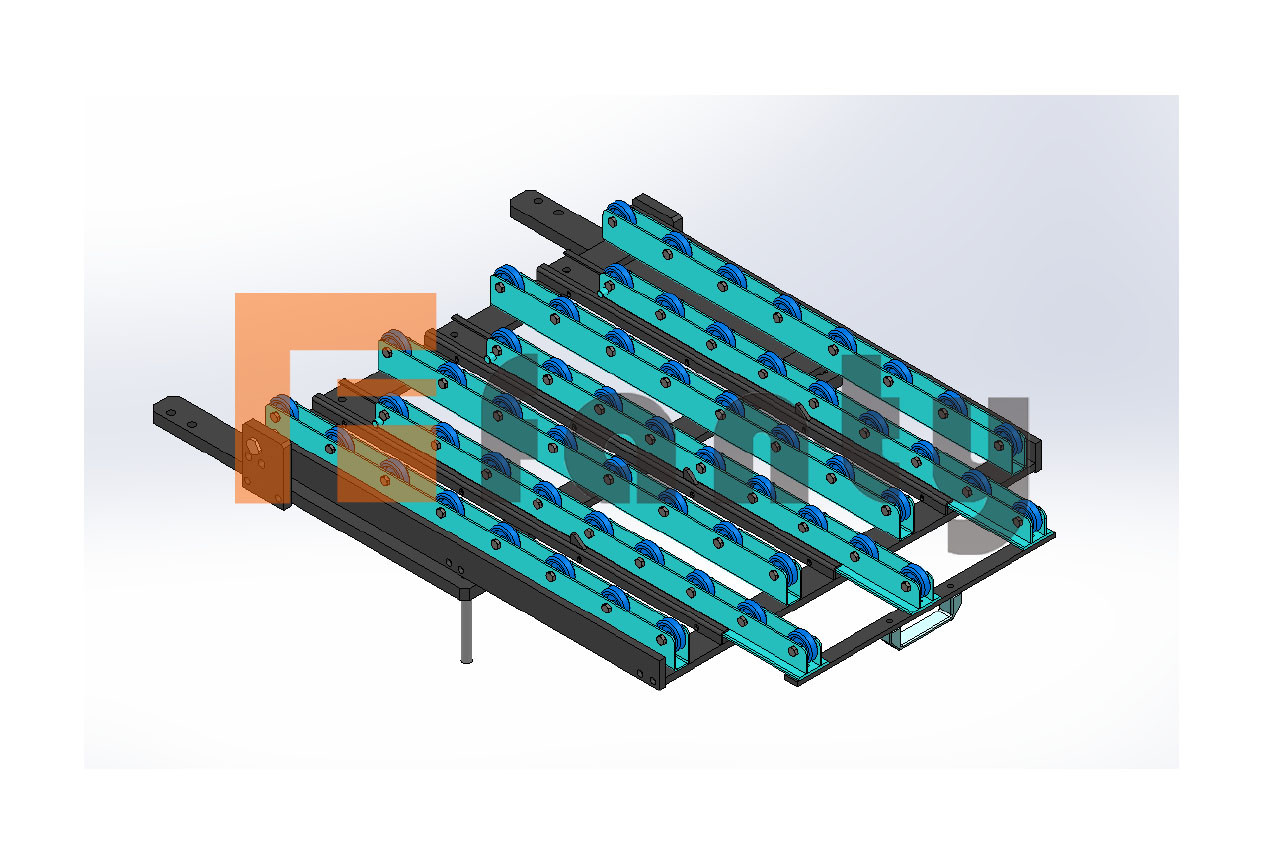

Discharge Port Supporting Rack Device

For smooth transmission between the fixed size feeding and the mold. The supporting frame is equipped with high-quality imported wear-resistant wheel.

* Fanty only provides the optional structurer according to customers' needs for their stamping line.

3. Structurer Running Test Video of Decoiler Straightener Feeder

What Coil Materials Can Decoiler Straightener Feeder Handle?

The Decoiler Straightener Feeder machine caters to a wide range of coil materials, including Cold rolled sheet, Pickling sheet, Galvanized sheet, Stainless steel, copper, as well as varying thicknesses. Its integrated design not only enhances productivity and reduces downtime but also ensures improved quality and repeatability of the manufacturing process.

Cold rolled sheet

Pickling Sheet

Galvanized Sheet

Stainless Steel

Subtypes within the Decoiler Straightener Feeder Group

3 products found

ViewShowcase

The Precision Decoiler Straightener Feeder is a specialized Steel Coil Handling equipment designed for handling steel coils

The Combination Decoiler Straightener Feeder, also called Uncoiler Straightener Feeder

The Decoiler Straightener Feeder Machine, also called Uncoiler Straightener Feeder, is a specialized Steel Coil Handling equipment

Brief Specification of Decoiler Straightener Feeder

Thickness: 0.3 mm – 3.2 mm

Coil Width: 50mm – 400/ 500/ 600/ 800 mm

Coil Weight: Max. 3 ton/ Max. 5 ton

Yield Strength: ≤245 N/mm²

Tensile Strength: ≤392 N/mm²

Material Thickness: 0.5 mm – 4.5 mm

Coil Wdith: 70 mm – 1300 mm

Coil Weight: 3ton/ 5ton/ 7ton/ 10ton

Yield Strength: ≤245 N/mm²

Tensile Strength: ≤392 N/mm²

Material Thickness: 0.6 mm – 6.0 mm

Coil Wdith: 70mm to 1600mm

Coil Weight: 5ton/7ton/10ton/15ton

Feeding Speed: 0-20m per minute

Feeding Accuracy: ±0.1 mm

Application

The Decoiler Straightener Feeder is indispensable in various industries, including automotive, electronics, appliance manufacturing, and more. It streamlines the processing of metal coils for stamping, forming, and punching applications.

• Automotive manufacturing

BYD Case

Audi Case

JMC Case

DFM Case

Fanty Production of Decoiler Straightener Feeder

Frequently Asked Questions

Equipment Performance

Q: Which Types Of Coil Materials Can Your DSF NC Straightener Feeder Equipment Handle?

Fanty: Our equipment can handle a variety of coil materials, including common low-carbon steel, galvanized sheet, medium and high-strength steel, copper, and stainless steel.

Q2: What Is The Applicable Range Of Material Thickness And Width?

Fanty: Different models of our nc straightener feeder equipment have different applicable ranges for material thickness and width. For example, a common model can handle materials with a thickness of 0.2 - 6.0mm, and the applicable width range of materials is 50 - 1600mm.

Q3: What Precision Can Be Achieved In Leveling And Feeding?

Fanty: In terms of leveling precision, we can control the flatness of the material within a very small range. Generally, the deviation per meter can be within ±0.5mm. For feeding precision, by adopting a high-precision servo control system, we can achieve a feeding precision of ±0.1mm, which can fully meet the requirements of industries with high processing precision needs, such as automotive stamping parts and electronic components manufacturing.

Production Efficiency

Q: What Is The Maximum Feeding Speed Of The Equipment?

Fanty: The maximum feeding speed of the decoiler straightener feeder equipment can reach 20 - 30 meters per minute, and the specific speed may vary depending on the thickness and material of the coil.

Q: How Is Its Ability To Work In Coordination With Punch Presses And Laser Cutting Machines?

Fanty: Our decoiler straightener feeder equipment has excellent coordination capabilities and can achieve automated linkage control with various equipment such as punch presses and laser cutting machines. By being equipped with an advanced control system and communication interfaces, it can accurately synchronize with other equipment to ensure the efficient and smooth operation of the production process.

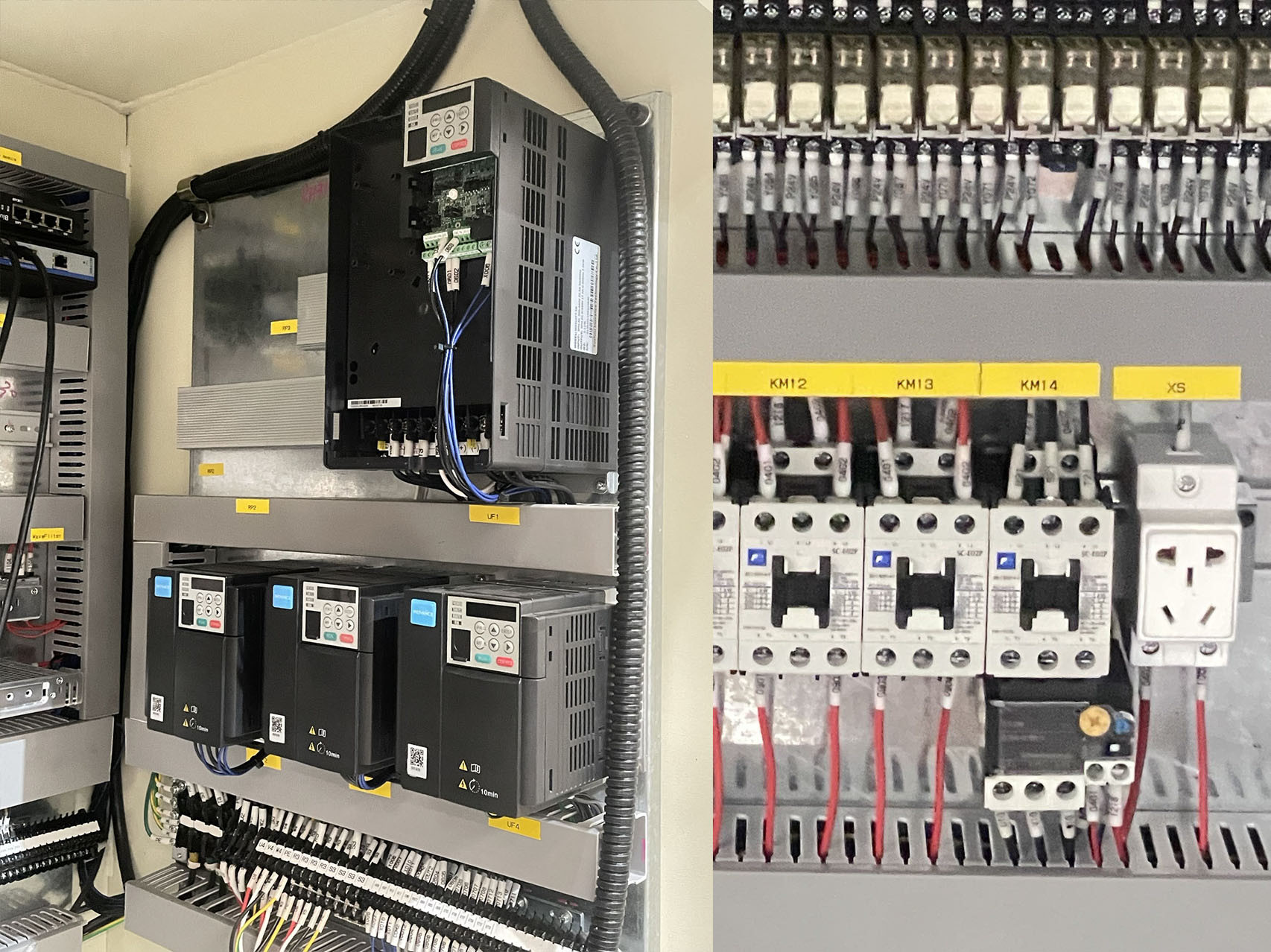

Q: What About The Stability And Durability Of The Uncoiler Straightener Feeder Equipment?

Fanty: We use high-quality metal raw materials, famous electronics and advanced manufacturing processes. Key components such as rollers and dies are specially heat-treated (HRC60 ± 2), which have high hardness and wear resistance. Moreover, we use the famous electronics from international brands like Schneider, Yaskawa, Mitsubishi...The overall structure of the equipment is robust, enabling long-term stable operation with a low failure rate. At the same time, we also provide a complete after-sales service system and regular maintenance suggestions to further extend the service life of the equipment.

Operation and Maintenance

Q: Is The Control System And Human-Machine Interface Of The Equipment Complex To Operate?

Fanty: Our decoiler straightener feeder equipment uses an advanced touch screen control system, and the human-machine interface is user-friendly, with simple and intuitive operation. Operators can get started after simple training.

Q: What Are The Daily Maintenance Tasks?

Fanty: The daily maintenance tasks of decoiler straightener feeder mainly include regularly checking the hydraulic oil system, cleaning the surface and internal dust and debris of the decoiler straightener feeder equipment, inspecting the wear condition of the rollers and dies, and replacing the vulnerable parts in a timely manner. The equipment is equipped with a complete fault diagnosis system.

Q: How Can We Troubleshoot And Solve Problems When A Malfunction Occurs?

Fanty: When a malfunction occurs to the decoiler straightener feeder, it will display clear fault codes and prompt messages on the display screen to help you quickly locate the problem. For some common malfunctions, you can troubleshoot and solve them according to the instructions in the equipment manual, and we will also provide you with remote technical support. If you encounter more complex problems, our professional after-sales service team will respond promptly and arrange personnel to conduct on-site maintenance.

Price & Cost

Q: What Is The Price Of The Equipment?

Fanty: The price of the decoiler straightener feeder equipment varies according to different configurations, models, and functional requirements. Send us inquiry to fanty@sz-fanty.com and we can quote it for you right now.

Q: Are There Different Configurations And Models Available For Selection?

Fanty: We offer a variety of configurations and DSF models decoiler straightener feeder for you to choose from, and you can select according to your own production needs and budget.

Q: How About The Operation Cost?

Fanty: In terms of operation cost, the motor power of the equipment varies according to different models, generally between 10 - 30kW, which is relatively energy-efficient. Regarding the cost of consumables, the replacement frequency of vulnerable parts such as rollers and dies depends on the usage frequency of the equipment and the characteristics of the production materials. Usually, the service life of the rollers is about 800 - 1000 hours, and the service life of the dies is about 50,000 - 100,000 stamping times. The replacement cost is relatively reasonable, and we will provide you with original factory accessories to ensure the quality and compatibility of the accessories.

After-sales Service

Q: What Is The Warranty Period Of The Equipment?

Fanty: Our decoiler straightener feeder equipment uses an advanced touch screen control system, and the human-machine interface is user-friendly, with simple and intuitive operation. Operators can get started after simple training.

Q: What Services Are Provided Within And Outside The Warranty Period Respectively?

Fanty: Within the warranty period, we will provide you with free equipment maintenance and repair services, as well as replace the parts that are damaged due to quality problems. After the warranty period, we will still provide you with high-quality after-sales services, and charge a reasonable maintenance fee and the cost of accessories.

Q: Can You Provide Technical Training?

Fanty: We will provide professional technical training for customers, including the operation method of the equipment, maintenance knowledge, troubleshooting skills, etc., to ensure that your operators can master the use and maintenance of the equipment proficiently. In addition, we also provide long-term technical support for customers. No matter what stage the equipment is in, if you encounter any problems, you can contact our technicians at any time, and we will serve you wholeheartedly.

Case Studies

subscription

Or send us messages online !

- *Tel

- *Title

- *Content