High labor intensity and low efficiency of manual work

In automotive parts manufacturing, there is a wide variety of components. Some parts may be heavy or have special dimensions. The traditional manual depalletizing and handling methods not only impose a high labor intensity, which is likely to cause fatigue and injuries to workers, but also have low work efficiency and are difficult to meet the needs of large-scale production.

Difficulty in ensuring precision

The production of automotive parts requires extremely high precision. During the manual handling of materials and transfer between workstations, it is very difficult to ensure that components are accurately placed in the specified position every time. This may affect the precision of subsequent processing and assembly, resulting in unstable product quality.

Insufficient production flexibility

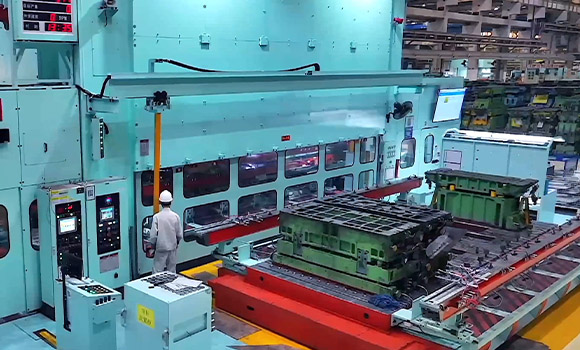

The automotive industry experiences rapid product updates. Automotive parts manufacturing enterprises need to frequently adjust the production line to adapt to the production requirements of components for different vehicle models. The traditional fixed production line layout and transfer methods of die changing have poor flexibility, and the adjustment is difficult, costly, and time-consuming.

Production efficiency restricted by the logistics link

In the production process of automotive parts manufacturing, the supply and transfer of materials are crucial links. If the depalletizing and transfer speed cannot keep up with the rhythm of the production line, it will lead to the production line stopping and waiting for materials, reducing the overall production efficiency.

High equipment reliability issues and maintenance costs

Some traditional mechanical transfer equipment or simple automated devices are prone to malfunctions during long-term operation, requiring frequent maintenance and replacement of components, which increases the maintenance costs of enterprises and the downtime.

Difficulty in quality traceability

In the automotive parts manufacturing industry, product quality traceability is an important task. In the traditional production mode, during the material flow process, it is very difficult to accurately record the source, processing process, and flow information of each component. Once a quality problem occurs, it is difficult to quickly and accurately trace the root cause of the problem.