How to Mast the Purchase of Decoiler Straightener Feeder for A Shelving Production in 2025 ?

In the high-quality shelving manufacturing, the acquisition of a Decoiler Straightener Feeder is a strategic move that can significantly influence a factory's production efficiency and product quality. However, this purchase decision is not without its complexities. Let's explore this crucial purchase from multiple perspectives, addressing the concerns and highlighting the key considerations for making an informed choice.

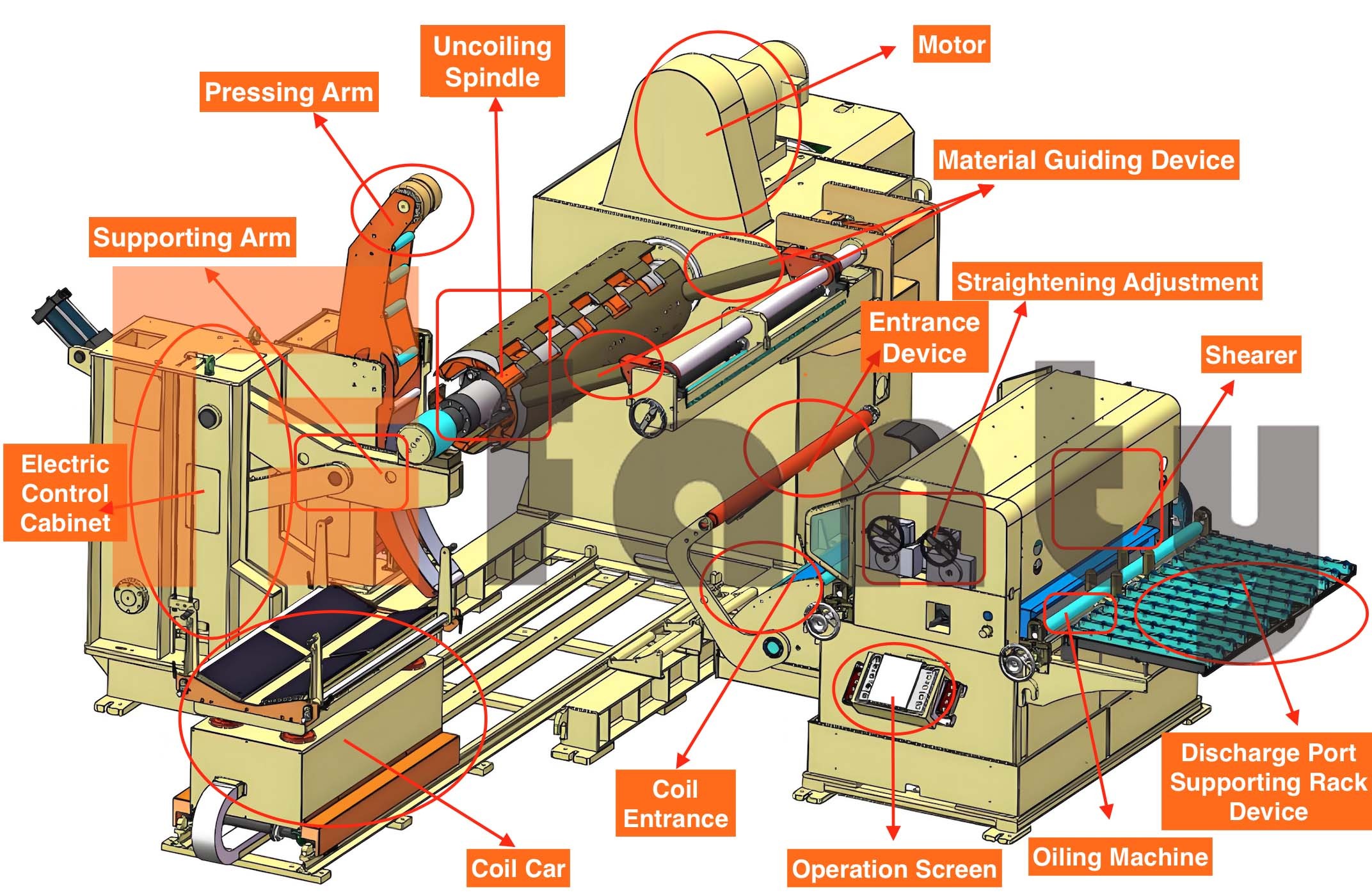

What's a Decoiler Straightener Feeder ?

Before we go deeply, let's know the Decoiler Straightener Feeder firstly. Basically, it is a compact machine that integrates decoiling fuction, straightening function and feeding function for coil handling from uncoiling to feeding process. You can learn its structurer from left diagram.

Decoiler Straightener Feeder has the following characteristics:

| ① Multi-functional integration | It Integrates the three functions of decoiling, straightening, and feeding into one unit, reducing the floor space of the equipment. | |

| ② High-precision | Equipped with a high-precision straightening device, it can effectively straighten metal coils of different thicknesses and materials. | |

| ③ High production efficiency | Decoiling, straightening, and feeding are carried out continuously, reducing the time loss of intermediate links and increasing the production speed. | |

How Decoiler Straightener Feeder Drives Coil Feeding Line Efficiency In Shelving Production ?

In shelving production, the coil feeding line is the backbone of the manufacturing process, and the decoiler straightener feeder is the driving force that significantly enhances its efficiency.

A normal process of a coil feeding line is: the decoiler smoothly unwinds large coils of metal, eliminating tangles and ensuring a continuous supply of material. The straightener then meticulously flattens the metal, removing any curvature or unevenness acquired during coiling. This precision preparation is crucial for the quality of shelving components. Finally, the feeder accurately and consistently advances the flat metal sheet at the required speed and distance, enabling precise cutting for each part.

By integrating these functions seamlessly, the decoiler straightener feeder streamlines the entire coil feeding line, reducing errors, minimizing downtime, and ultimately driving up the overall efficiency of shelving production.

When you are the following, what should you focus on when choosing a manufacturer of Decoiler Straightener Feeder ?

1-Owner's Perspective

As a shelving factory owner, your focus is on the big picture – how the decoiler straightener feeder will contribute to the overall success of your business.

Return on Investment (ROI):

The primary concern is ensuring that the purchase will yield a substantial ROI. Look for a machine that can boost production speed without sacrificing quality. A high-quality decoiler straightener feeder can increase the output of shelving components, allowing you to take on more orders and generate higher revenues. For example, a machine with advanced servo-driven feeding systems can achieve faster and more accurate material feeding, reducing production time per unit. Additionally, consider the long-term cost savings, such as lower energy consumption and reduced maintenance expenses, which can further enhance the ROI.Quality Assurance:

Your reputation in the market hinges on the quality of your shelving products. The decoiler straightener feeder should be able to consistently deliver flat and precisely fed materials, ensuring that the final shelves are of the highest quality. Check for features like high-precision leveling rollers and automatic tension control, which can minimize material defects and improve the overall quality of your production.Scalability & Flexibility:

As your business grows, you need a machine that can adapt to changing production requirements. Look for a decoiler straightener feeder that offers flexibility in handling different materials (such as steel, aluminum, or stainless steel) and various coil sizes. This scalability will allow you to diversify your product offerings and meet the demands of a wider range of customers.Supplier Relationship:

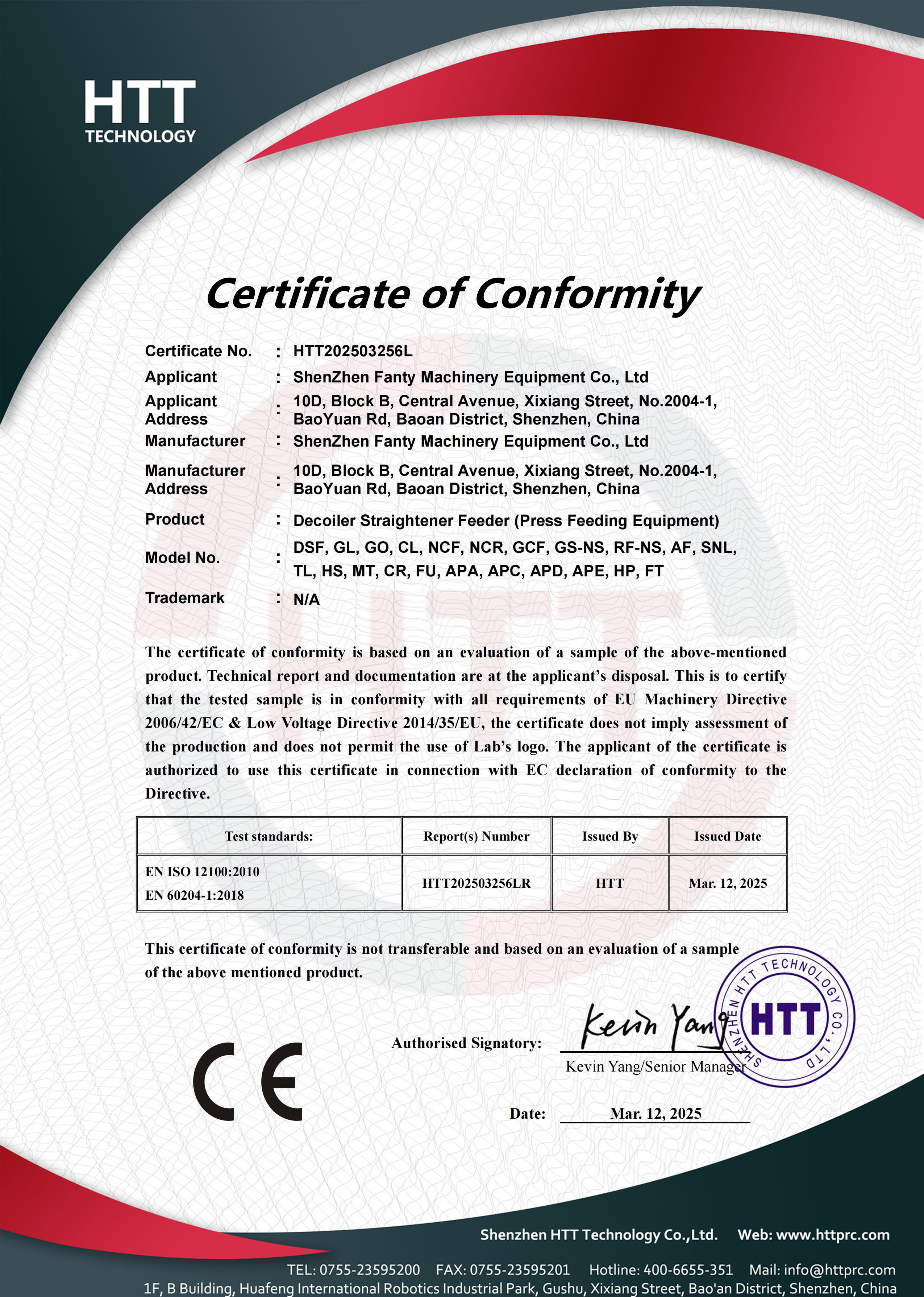

Building a strong relationship with the equipment supplier is crucial. A reputable supplier like Fanty, with a proven track record of reliability, excellent customer service, and a commitment to innovation, can be your ideal partner. Fanty not only provides high - quality decoiler straightener feeders but also offers technical support, training, and readily available spare parts, ensuring minimal downtime in case of any issues.

2-Engineer's Perspective

Engineers play a vital role in evaluating the technical aspects of the decoiler straightener feeder to ensure it meets the production requirements.

Technical Specifications:

Thoroughly review the machine's technical specifications, including the maximum decoiling weight and width, leveling accuracy, feeding speed, and repeatability. These parameters should align with your production needs and the quality standards you aim to achieve. For instance, if you produce heavy-duty shelving, you'll need a machine with a high maximum decoiling weight and robust leveling capabilities.Mechanical and Electrical Design:

Examine the machine's mechanical and electrical design for durability, reliability, and ease of maintenance. A well-designed machine with high-quality components will have a longer lifespan and require fewer repairs. Look for features like modular construction, which makes it easier to replace or upgrade individual components, and advanced electrical controls that offer precise and consistent operation.Automation and Integration:

In today's manufacturing landscape, automation is key to improving efficiency and reducing errors. Consider a decoiler straightener feeder that offers advanced automation features, such as automatic coil loading, self-adjusting leveling settings, and integration with your existing production line. This seamless integration can streamline your production process and improve overall productivity.Safety Features:

Ensure that the machine is equipped with comprehensive safety features to protect your operators. This includes emergency stop buttons, safety guards, and sensors that detect and prevent potential hazards. A safe working environment not only safeguards your employees but also helps you comply with regulatory requirements.3-Procurement Manager's Perspective

Procurement managers are responsible for making sure the purchase is cost-effective and that the supplier meets all the necessary requirements.

Cost Analysis:

Conduct a detailed cost analysis that includes not only the initial purchase price but also the total cost of ownership (TCO). The TCO encompasses factors such as energy consumption, maintenance costs, spare parts availability, and potential downtime. Compare the TCO of different models and suppliers to find the most cost-effective option without compromising on quality.Supplier Evaluation:

Evaluate potential suppliers based on their reputation, financial stability, production capacity, and customer reviews. Request references and case studies from the supplier to get a better understanding of their track record in providing reliable equipment and excellent service. Additionally, consider the supplier's location and proximity to your factory, as this can impact delivery times and after-sales support.Contract Negotiation:

Once you've selected a supplier, negotiate the contract terms carefully. Pay attention to details such as the delivery date, payment terms, warranty period, and after-sales service obligations. A well-negotiated contract will protect your interests and ensure a smooth transaction.Market Research:

Stay updated on the latest trends and technologies in decoiler straightener feeders by conducting regular market research. This will help you identify new products and features that can give your factory a competitive edge. Additionally, it can help you benchmark the prices and performance of different suppliers, enabling you to make more informed purchasing decisions.Conclusion

Mastering the purchase of a decoiler straightener feeder for shelving production requires a comprehensive approach that takes into account the perspectives of the factory owner, engineer, and procurement manager. By carefully evaluating the machine's performance, quality, cost-effectiveness, and supplier support, you can make a decision that will benefit your business in the long run. Remember to prioritize your specific needs and goals, and don't be afraid to ask questions and seek expert advice. With the right decoiler straightener feeder, you can enhance your production capabilities, improve product quality, and drive the success of your shelving manufacturing business.