What Are The Advantages of a 3-in-1 Decoiler Straightener Feeder Machine ?

In the fast-paced world of manufacturing, efficiency and versatility are key to maintaining a competitive edge. The Decoiler Straightener Feeders machine have emerged as a revolutionary solution for coil processing, combining multiple functions into a single unit. This article explores the numerous advantages of utilizing a Decoiler Straightener Feeder, also called Uncoiler straightener feeder machine, highlighting its impact on productivity, cost-effectiveness, and operational flexibility.

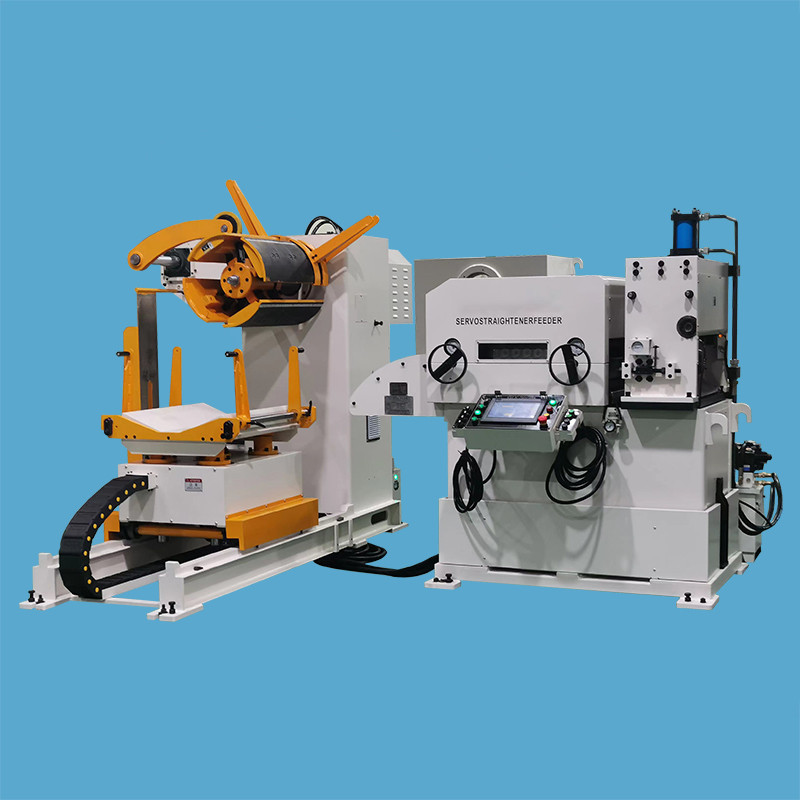

Understanding the Decoiler Straightener Feeder Machine

A decoiler straightener feeder machine integrates three essential functions: uncoiling, straightening, and feeding materials into the production line. This all-in-one solution simplifies the coil processing workflow, reducing the need for multiple machines and minimizing space requirements.

Decoiler Straightener Feeder Machine

Send us inquiry for your press line !

Fanty@sz-fanty.com

Key Components of a Decoiler Straightener Feeder Machine

Uncoiler: Automatically unwinds coils, ensuring a steady supply of material for processing.

Straightener: Aligns and flattens the material, preparing it for accurate feeding.

Feeder: Delivers the material to the next stage of production with precision and consistency.

Advantages of Using a Decoiler Straightener Feeder Machine

1. Enhanced Efficiency

The integration of multiple functions into a single machine significantly enhances operational efficiency. By eliminating the need for separate machines, manufacturers can streamline their processes, reducing cycle times and increasing throughput.

Efficiency Metrics

Reduced Setup Time: With a decoiler straightener feeder machine, setup times are minimized, allowing for quicker transitions between production runs.

Continuous Operation: The machine can operate continuously, ensuring a steady flow of materials without interruptions.

2. Space-Saving Design

Manufacturing facilities often face space constraints. The compact design of a decoiler straightener feeder machine allows manufacturers to optimize their floor space while still achieving high levels of productivity.

Space Optimization Benefits

Reduced Footprint: Combining three functions into one unit frees up valuable floor space for other essential equipment.

Simplified Layout: A streamlined layout enhances workflow efficiency, reducing the time spent moving between machines.

3. Cost-Effectiveness

Investing in a decoiler straightener feeder machine can lead to significant cost savings over time. The initial investment is often offset by reduced operational costs and increased productivity.

Financial Advantages

Lower Capital Expenditure: Purchasing a single machine instead of three separate units reduces initial capital outlay.

Decreased Maintenance Costs: Fewer machines mean lower maintenance and repair costs, contributing to overall savings.

4. Improved Material Handling

The 3-in-1 feeder machine enhances material handling capabilities, ensuring that materials are processed efficiently and accurately.

Material Handling Benefits

Consistent Feed Rates: The feeder component ensures that materials are delivered at consistent rates, reducing the risk of jams and misalignment.

Minimized Material Waste: Accurate straightening and feeding reduce material waste, contributing to more sustainable manufacturing practices.

5. Versatility in Applications

The versatility of a decoiler straightener feeder machine makes it suitable for a wide range of applications across various industries, including automotive, electronics, and metal fabrication.

Application Flexibility

Adaptable to Different Materials: The machine can handle various coil materials, including steel, aluminum, and plastic, making it a valuable asset for diverse manufacturing needs.

Customizable Settings: Many decoiler straightener feeder machines offer customizable settings to accommodate different production requirements.

What Decoiler Straightener Feeders Does Fanty Producing ?

Thickness: 0.3 mm – 3.2 mm

Coil Width: 50mm – 400/ 500/ 600/ 800 mm

Coil Weight: Max. 3 ton/ Max. 5 ton

Yield Strength: ≤245 N/mm²

Tensile Strength: ≤392 N/mm²

Material Thickness: 0.5 mm – 4.5 mm

Coil Wdith: 70 mm – 1300 mm

Coil Weight: 3ton/ 5ton/ 7ton/ 10ton

Yield Strength: ≤245 N/mm²

Tensile Strength: ≤392 N/mm²

Material Thickness: 0.6 mm – 6.0 mm

Coil Wdith: 70mm to 1600mm

Coil Weight: 5ton/7ton/10ton/15ton

Feeding Speed: 0-20m per minute

Feeding Accuracy: ±0.1 mm

Conclusion

The decoiler straightener feeder machine represents a significant advancement in coil processing technology. By integrating uncoiling, straightening, and feeding functions into a single unit, manufacturers can enhance efficiency, save space, and reduce costs. The versatility and improved material handling capabilities further solidify the decoiler straightener feeder machine as an essential tool for modern manufacturing operations.

Incorporating a decoiler straightener feeder machine into your production line not only optimizes coil processing but also positions your business for sustained growth and success in an increasingly competitive market. Embracing this innovative technology is a strategic move towards achieving operational excellence and maximizing productivity.

For customized your press line, contact us fanty@sz-fanty.com