Get A Close Eye On Eccentric Swing Type NC Servo Feeder !

In the dynamic landscape of stamping production, the eccentric swing type NC servo feeder, also called Zigzag Feeder, has emerged as a game-changer, offering unparalleled precision, efficiency, and versatility as a type press feeder. This innovative coil feeder technology has revolutionized the way manufacturers approach metal stamping processes, enabling enhanced productivity and quality outcomes. In this comprehensive guide, we will explore the transformative capabilities of the eccentric swing type NC servo feeder and its impact on stamping production.

Understanding the Eccentric Swing Type NC Servo Feeder

● Material thickness:0.2-3.2mm

● Handle steel coil thickness:0.2~2.0

● Feed length: 9999.99mm max.

● Feed roller: 2 pcs totally, 1pc upper, 1pc bottom.

● Speed: 20m/min feeding speed, 30m/min zigzag movement speed.

● Single-step migration save coil more than 1/4

● Suitable for circle steel sheets processing

● Save coil

The eccentric swing type NC servo feeder is a cutting-edge feeding system that combines the precision of servo technology with the flexibility of eccentric motion. This unique design allows for accurate feeding of metal sheets with varying thicknesses and shapes, ensuring consistent performance across a wide range of stamping applications. Key features of the eccentric swing type NC servo feeder include:

* High Precision: The servo-driven mechanism enables precise feeding control, minimizing material waste and enhancing part accuracy.

* Versatile Feeding: The feeder can accommodate different material types, sizes, and thicknesses, making it ideal for diverse stamping requirements.

* Efficient Operation: The eccentric swing motion optimizes material flow and reduces downtime, maximizing production efficiency.

* User-Friendly Interface: Intuitive controls and programming options simplify operation and setup, streamlining production processes.

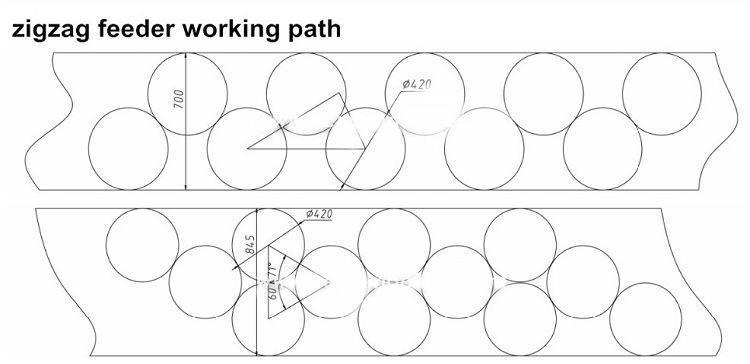

Working Path of Precision Zigzag Servo Feeder Machine

Benefits of the Eccentric Swing Type NC Servo Feeder

The adoption of the eccentric swing type NC servo feeder offers a myriad of benefits that elevate stamping production to new heights. Some of the key advantages include:

* Improved Productivity: The feeder's high-speed operation and precise feeding capabilities boost productivity and reduce cycle times.

* Enhanced Quality: Consistent material feeding results in superior part quality and dimensional accuracy, minimizing rework and scrap.

* Cost Efficiency: Reduced material waste, lower maintenance requirements, and increased uptime contribute to overall cost savings.

* Flexibility and Adaptability: The press feeder's ability to handle a wide range of materials and part geometries enhances production flexibility.

Integrating the Eccentric Swing Type NC Servo Feeder into Your Workflow

To leverage the full potential of the eccentric swing type NC servo feeder in your stamping production, consider the following integration strategies:

* Training and Familiarization: Provide comprehensive training to operators on the operation and maintenance of the feeder to ensure optimal performance.

* Process Optimization: Fine-tune feeding parameters and programming settings to maximize efficiency and quality output.

* Regular Maintenance: Implement a proactive maintenance schedule to keep the feeder in peak condition and prevent unexpected downtime.

* Continuous Improvement: Seek feedback from operators and monitor performance metrics to identify areas for enhancement and refinement.

Conclusion

In conclusion, the eccentric swing type NC servo feeder, or zigzag feeder, represents a paradigm shift in stamping production, offering unmatched precision, efficiency, and versatility. By embracing this innovative technology and optimizing its integration into your workflow, you can elevate your manufacturing processes to new levels of excellence and competitiveness.