A thorough explanation of the uncoiler's stop arm.

The decoiler, as a steel coil handling equipment, are also called uncoiler. A unique material stop mechanism needs to be employed in order to limit the material coil while the decoiler is operating. Its two goals are as follows: first, it keeps the material roll level with the production line throughout the uncoiling process to prevent the uncoiling material belt from deflecting. In order to keep the material roll from slipping and collapsing on the supporting tile, the second step is to restrict the location of the roll.

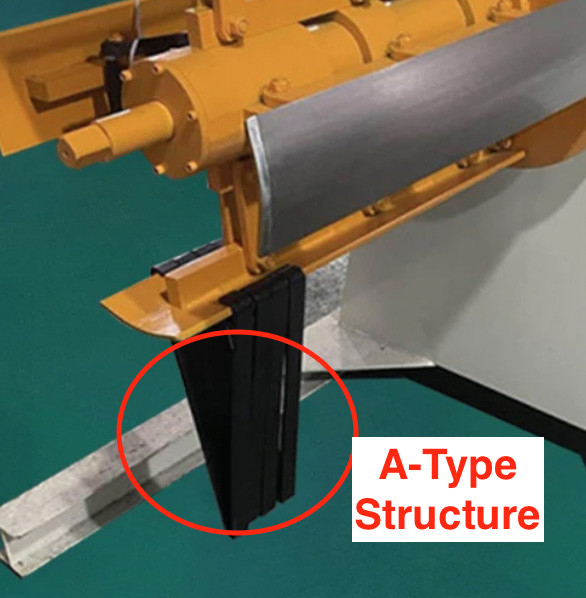

A-type iron structure is typically used as the stopper limit mechanism in ordinary uncoilers.

The conventional uncoiler's A-type iron structure is used to shrink the expansion and contraction reel and insert it into the material roll after first locating and locking the two A-type irons structure at the inner limit with bolts. Next, bring the material roll in close to the inner A-type iron structure. Using hydraulic expansion or by hand, tighten the material roll. Installing the outer A-type iron structure on the support tile is the last step in the material blocking process. After adjusting the distance multiple times based on the width of the material, lock the A-type iron bolts.

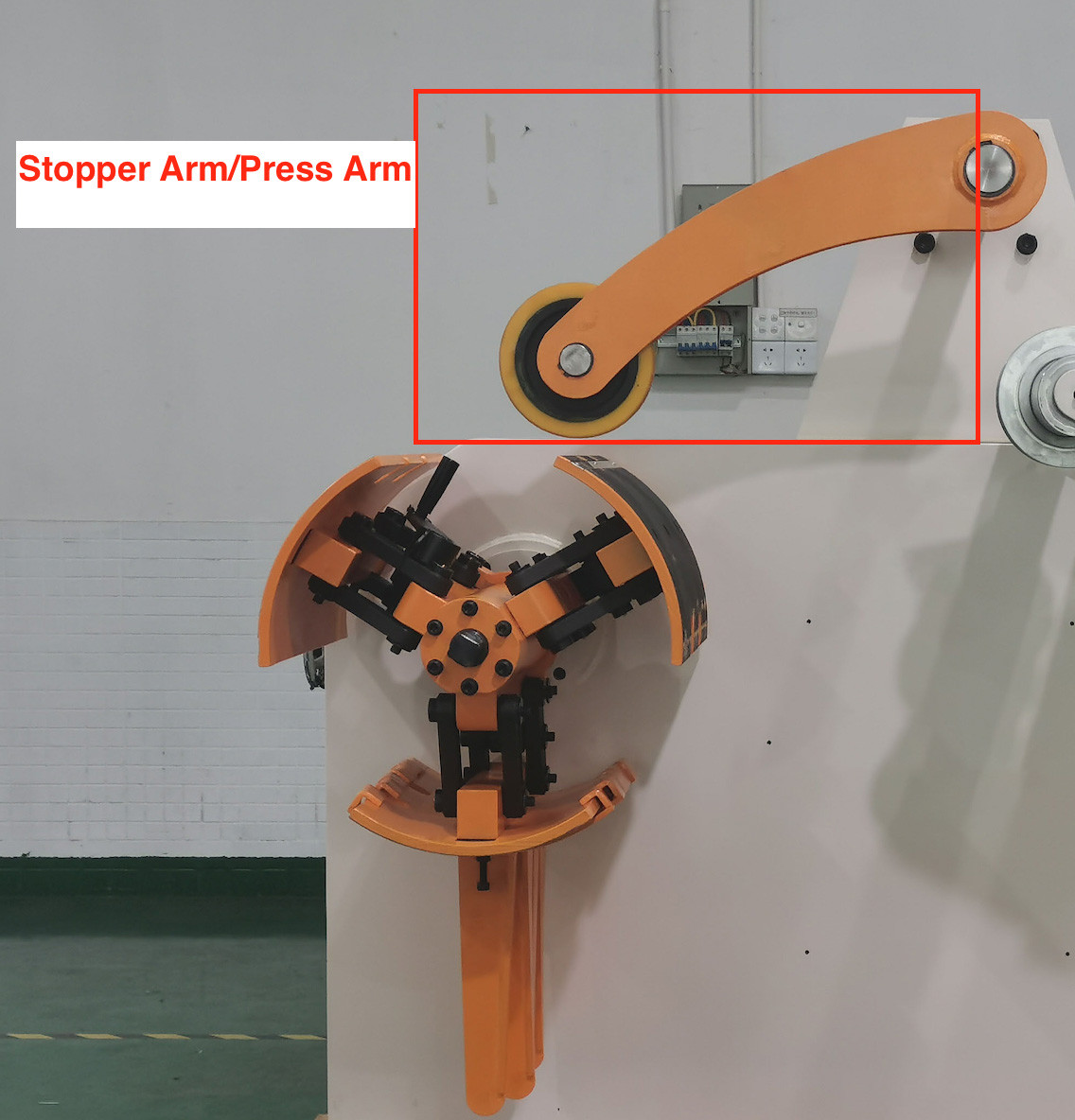

The basic uncoiler's material stop mechanism is widely used and has a low cost, straightforward construction, and good material stop effect. There is one glaring drawback, though, which is that it works best at the material roll's narrowest limit. Large material roll widths will cause issues including protracted installation times, difficult and time-consuming debugging, and inadequate material blocking effectiveness. At this time, it is required to employ the stopper arm to limit the position.

The uncoiler's stopper limit mechanism uses the stopper arm, a unique substitute for the stopper A-type iron. It operates simply, takes less time, and is ideal for a variety of wide and large rolls with varying material blocking limits. It is powered by an air cylinder to achieve fully autonomous material blocking.

To avoid the reel clashing with the retaining rods and minimize needless damage, the stop rod of the stop wheel devices can be elevated upwardly when the reel is loaded. After the material roll is placed on the expansion and contraction reel of the uncoiler, the stop rods of each stop wheel device are lowered. Additionally, it is modified by the corresponding moving parts to restrict the material roll to the feeding position. The elastic body can be utilized to create a buffer effect when the stop rod of the stop wheel device is near to the material roll. This is an easy and practical way to extend the service life.This is the purpose of the stop arm.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder