Optimizing and Enhancing the Uncoiler

In the stamping manufacturing line, the decoiler, as the steel coil handling equipment, is a frequently used auxiliary device that has reached a reasonably advanced stage of development in the market. Additionally, a lot of manufacturers have moved on to mass-manufacture it as a standard model while ignoring the two significant structural flaws that remain. I will next go over FANTY's optimization, improvement, and uncoiler for these two areas.

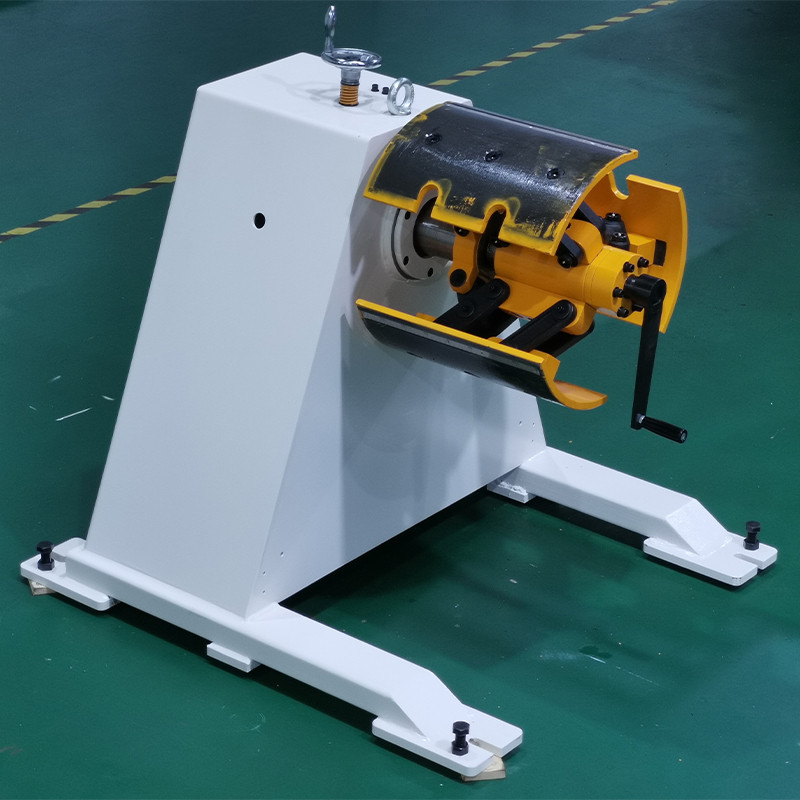

1. The uncoiler's expansion and contraction reel is made up of four arc-shaped support tiles with gaps allowing for expansion and contraction.

The support tiles of the uncoiler that is widely available on the market are joined together in a straight seam. Because of the material tail's considerable curvature, it frequently becomes stuck in the space between the supporting tiles while in operation and hooks on them, damaging the uncoiler.

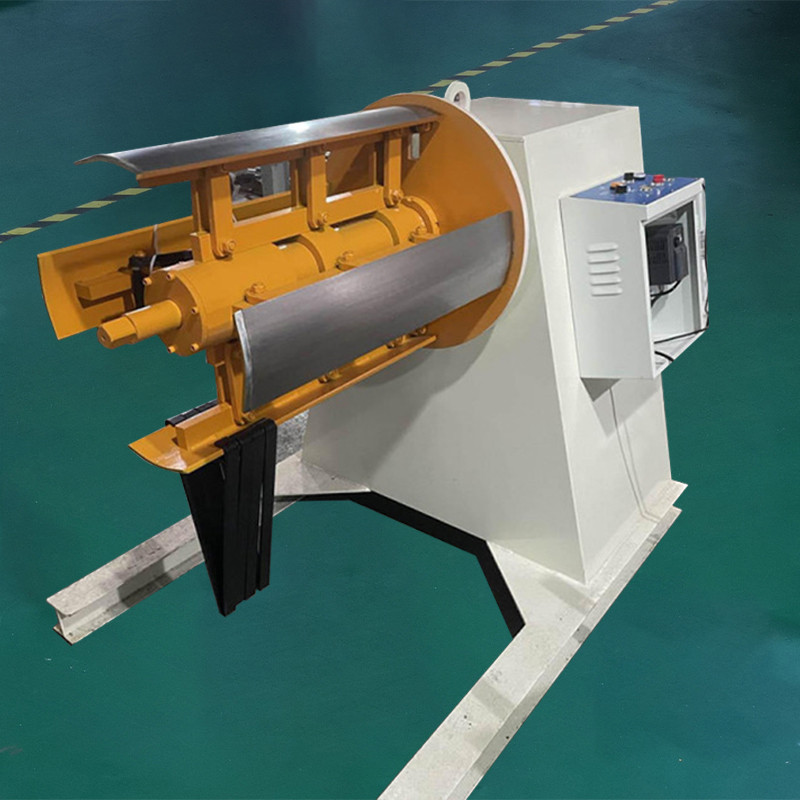

2. To stop the coil from deviating, four A-type stop irons are mounted on the uncoiler's support tile.

Nevertheless, this A-type retaining iron is difficult to load, unload, and fix, which has a significant impact on production efficiency in real manufacturing.

To address these two significant shortcomings, FANTY Machinery created two significant structural enhancements to the uncoiler:

1. Instead of using the conventional four-piece arc structure for its supporting tiles, FANTY's uncoiler uses scraped and staggered supporting tiles.

The issue of damage to the uncoiler resulting from the tail of the material becoming stuck is essentially resolved by the staggered arrangement of the support tiles, as well as the very short staggered straight seam.

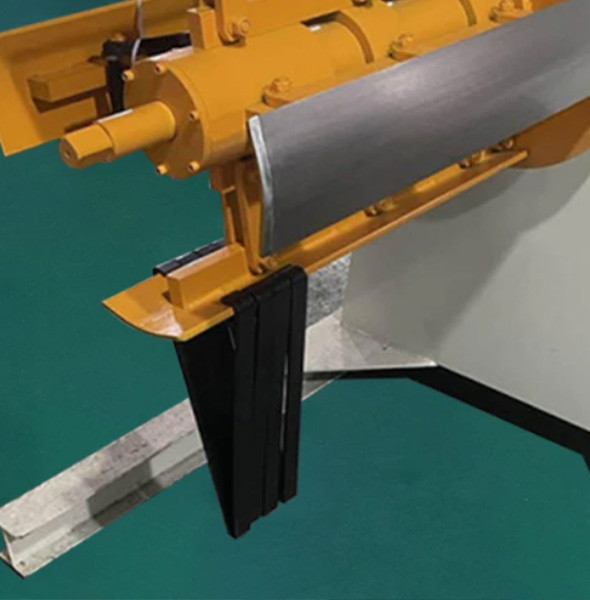

2. A T-type quick-change structure is used in place of FANTY's A-type iron in the uncoiler.

Two T-shaped slots on the supporting tile are created when the uncoiler is constructed, and T-shaped bolts secure both the supporting tile and the holding iron. Simultaneously, the retaining iron can not only move along the T-shaped groove to adjust to varying material widths in order to prevent material deflection, but it can also fundamentally realize quick change, make retaining iron loading and unloading simpler, and make customer use easier.

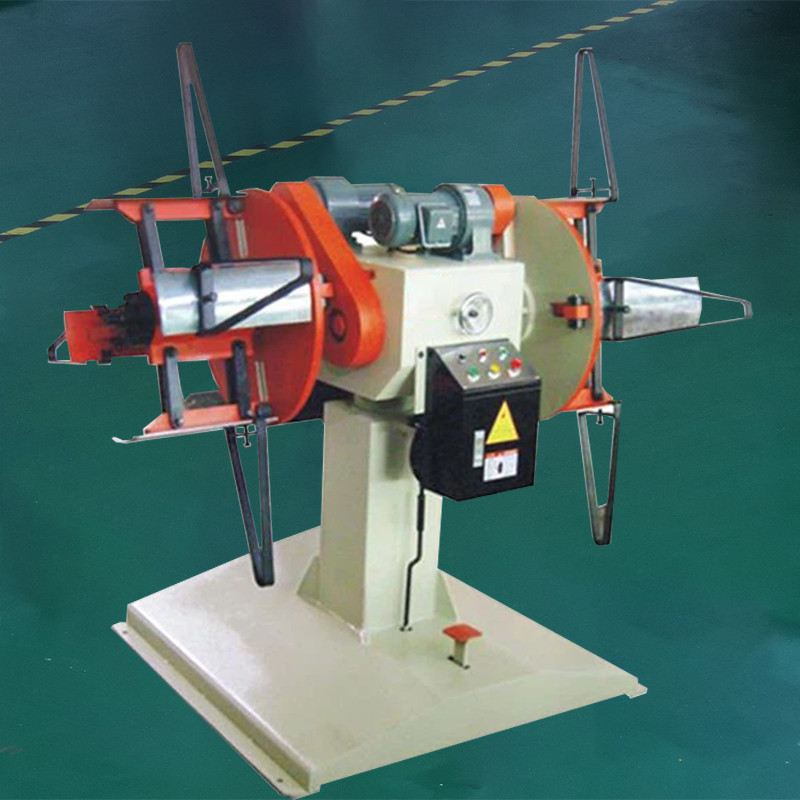

What types decoiler does fanty produce?

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder