Decoiler Machine Operating Instructions

Generally, the decoiler's operation instructions consist of six points.

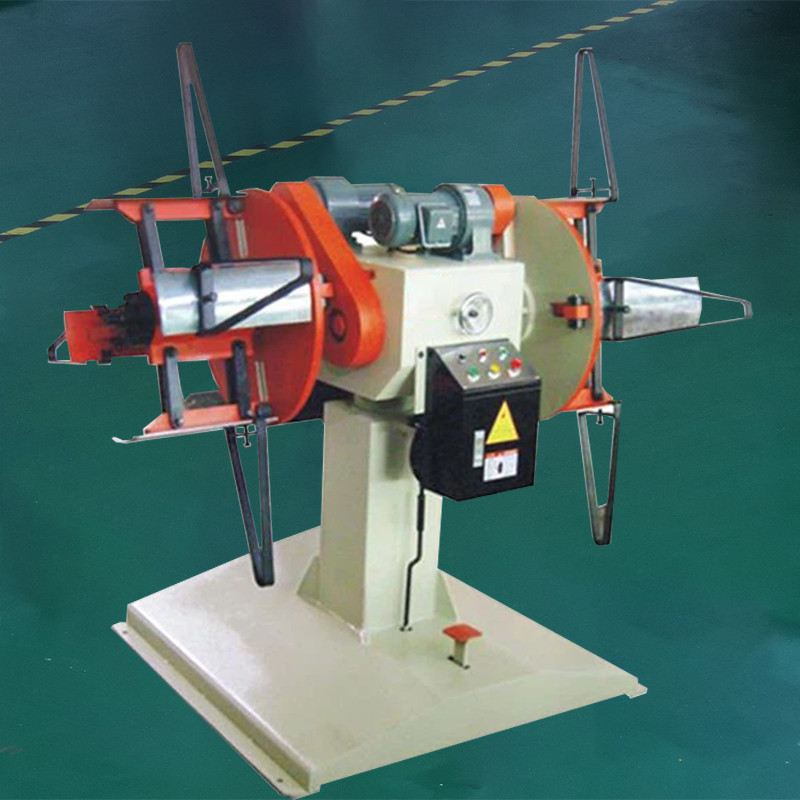

1. Activate the 380V three-phase power supply, initiate the decoilers, and verify the direction of rotation; the material ought to be supplied vertically and in the direction of the 24V induction frame. (We will, of course, set up the power conversion for your local use.)

2. Modify the decoiler's distance and position in relation to the material's thickness and the coil leveler or feeder machine's location to enable the material to enter the device smoothly. A certain waiting area needs to be changed based on the feeding length if the coil feeder machine is the sole one being used. The distance from the feeding port of the feeding device is 4 to 4.5 meters when the height of the decoiler's center is about equivalent to the punch press's working surface. Adjust the discharge direction and feeding distance accordingly when it is too high or too low.

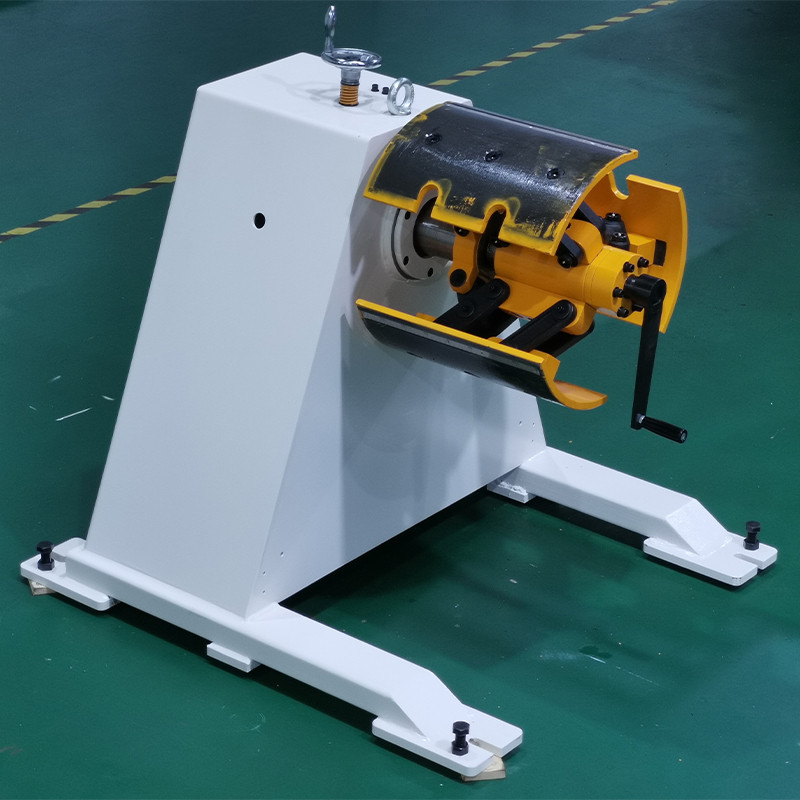

3. To change the support plate's diameter (which should be less than the material's inner diameter), turn the decoiler's handle counterclockwise. Install the baffle plate on the other two material plates after loading the coil material, rotating the decoiler's handle clockwise, and tightening the coil material's inner circle. It should be mentioned that the material indicates that the baffle plate cannot grip the coil material too tightly; instead, there should be a 2 to 5 mm gap to prevent the discharge from being impacted. To securely retain the coil material, turn the decoiler handle clockwise.

4. Modify the height of the 24V induction frame and appropriately regulate the discharge duration based on manufacturing requirements.

5. The feeding speed is directly adjustable on the panel during automatic operation, thanks to inductive control. If the manual function is needed, press the jog button after choosing the manual adjustment direction (forward or reverse) on the panel. The speed can also be changed at this point.

6. You should press the emergency stop switch right away if the decoiler machine is feeding abnormally; the press punching machine will stop at the same moment. The press punching machine can be formally started after the irregularity has subsided and the emergency stop switch has been reset (turned off).

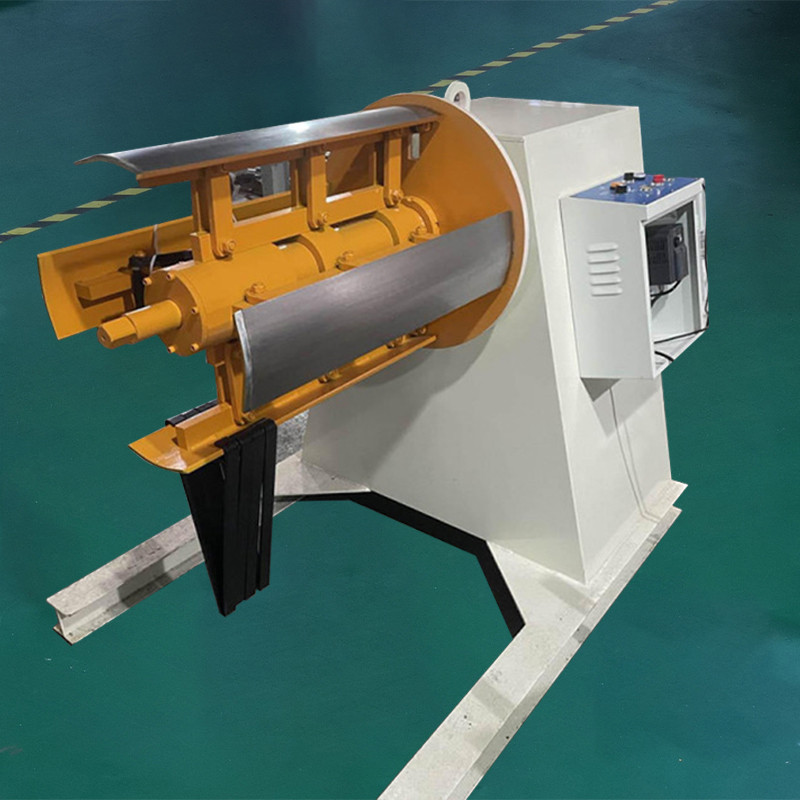

Select the type of decoiler machine that you need first. There are five types of decoilers.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder