Using an uncoiler to control the unwinding of non-conductive material

Using an uncoiler to control the unwinding of non-conductive material

Certain materials, like certain silicon steel sheet, surface-coated materials, and non-metallic materials, have surfaces that are not particularly conductive when used in stamping manufacture. The automatic start and stop functions cannot be achieved if a normal uncoiler is employed since these materials are not electrically conductive. The induction apparatus has to be adjusted.

In accordance with customers' actual needs, FANTY Machinery offers two techniques of modification:

1. Handle the uncoiler's automated start and stop using the opposite-beam photoelectric sensor switch. The height at which the uncoiler must start and stop is where the opposite-beam photoelectric switch is mounted. The photoelectric switch controls the uncoiler's stop when the uncoiler material sags to a point where it blocks the opposing beam. When the material is taken out of the opposing light's position, the machine that follows can start up again.

2. To regulate the uncoiler's automated start and stop, utilize the micro switch. Place the micro switch in the waiting area for the feeder, the leveler that comes next, and the uncoiler. Secure it with a floor bracket. The micro switch transmits a control signal to the intermediate relay in the uncoiler box, instructing it to stop the uncoiler's motor when the uncoiler tape sags and comes into contact with it.

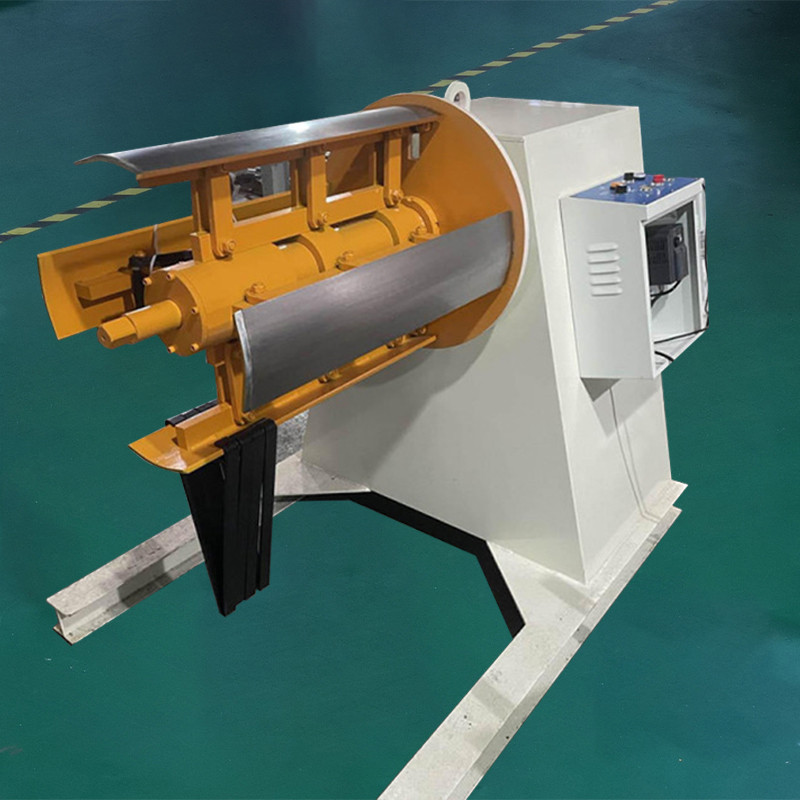

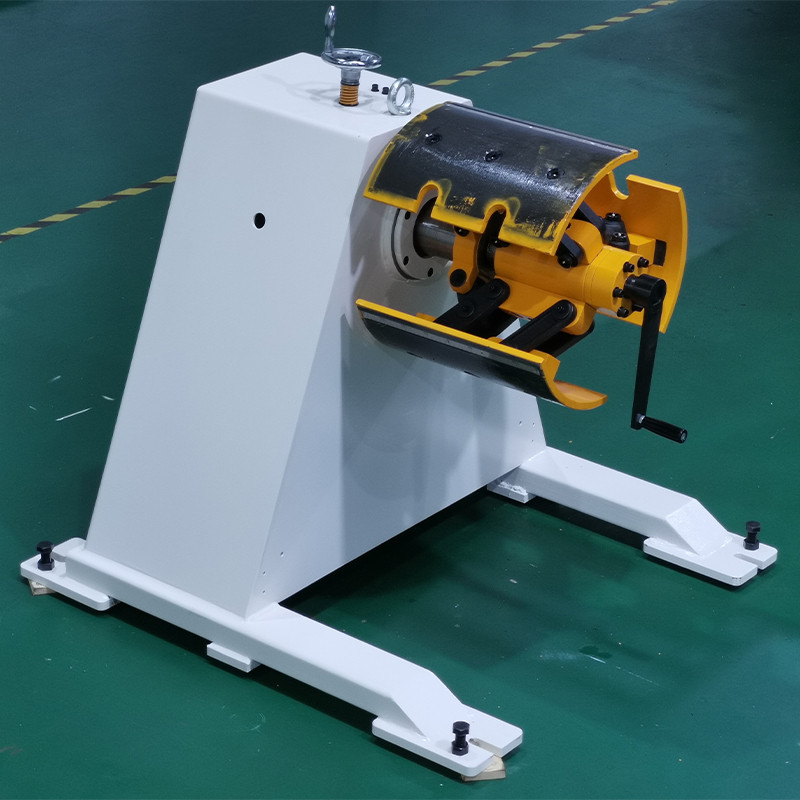

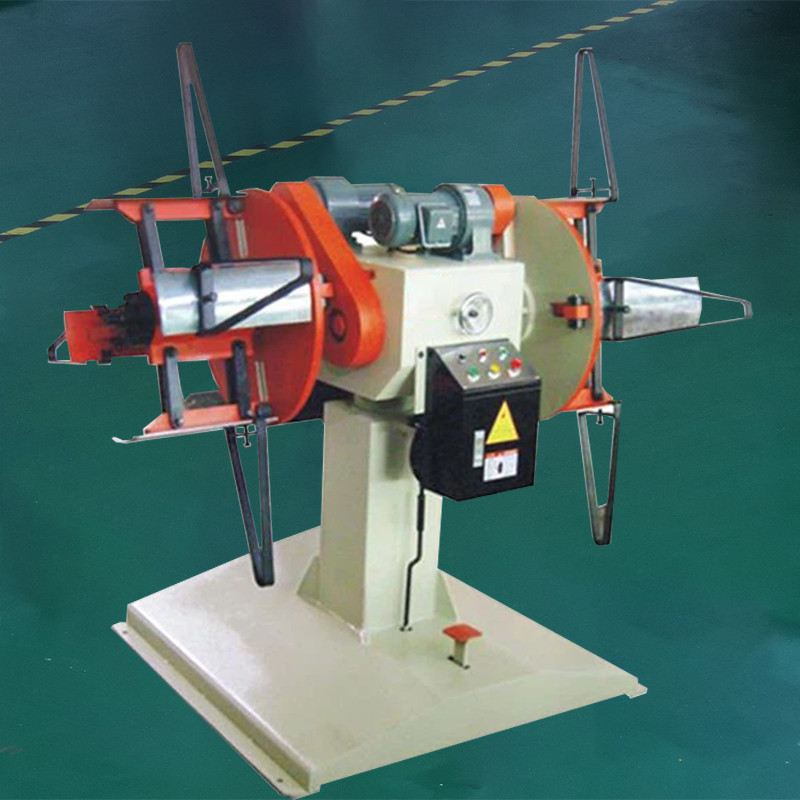

FANTY Uncoiler/Decoiler Equipments

The safety measures for using the decoiler machines are listed above. You can reach us personally at fanty@sz-fanty.com with any inquiries, and we'll assist you in resolving the issue.

Click Here for more information about decoiler machine for your press line.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder