Issues with Feed Slipping on Servo Feeders and Their Solutions

One of the most often used coil handling devices available is the NC servo feeder. Pneumatic and mechanical servo feeder machines are available from FANTY Machinery. Stampers occasionally discover inaccurate feed action; in certain cases, this even causes the entire stamping line to stop operating. The majority of incidents are caused by feed slipping; let's examine this in depth to see why and how to fix it.

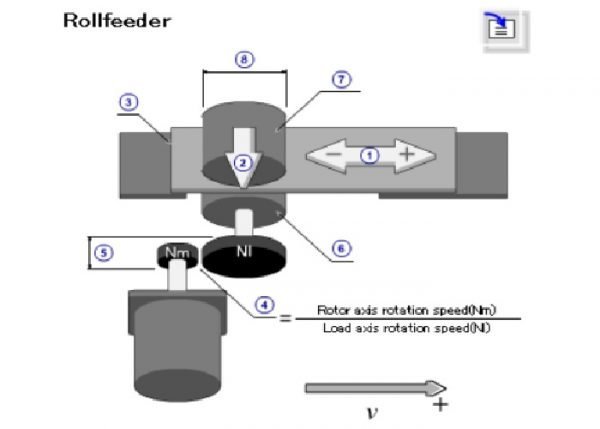

Anylasis for Servo Feeder Feed Slippage

The servo feeder, as depicted in the diagram, is a device that feeds material forward using two rollers. The lower roller is powered by a servo motor, and the upper roller is actuated by a timing belt drive.

We can see from this structural study that there are primarily two causes of slipping:

1, There is not enough friction between the material and the roller;

2, The material is not sufficiently tensioned on the roller;

Increasing pressure or altering the coefficient of friction between the material and the roller are the two methods available to enhance the friction between them. Generally, the easiest and most straightforward way is to increase the pressure. If the material can be fed regularly but there is an infrequent incidence of retracement, this usually indicates that there is not enough pulling power. It frequently happens when the substance approaches or beyond the feeding threshold. You can modify it in accordance with the following plan (please get in touch with our business if there are any issues).

The thick material is primarily to blame for the servo feeder's material slippage. The aforementioned study indicates that the material can be modified from the following three angles when it slips:

* To raise the roller's pressure on the mechanical servo feeder, modify the roller's pressure spring on the feed. To raise the pressure (die spring pressure of the same specification: green > red > blue > yellow), a stronger pressure spring (such as green) might be used in its place if it turns out to be yellow.

* Verify whether the cylinder of the pneumatic servo feeder is attached to a single air pipe. The cylinder will only function when it is relaxed if there is just one air pipe. Sending the thick plate material is possible since clamping is entirely dependent on the pressure spring. Simultaneously, a condition occurs where the clip slips and does not tighten. In order for the cylinder to produce a particular thrust and keep the roller on the servo feeder gripped firmly so that it does not slip, a gas line must now be connected to the cylinder on the solenoid valve.

* In order to minimize waiting area and lower the material weight of the waiting area, the distance between the feeder and the sheet linearener or decoiler machine should be decreased as much as feasible once the servo feeder's feeding speed is reached. When there is too much material in the waiting area, the servo feeder may slip. This can be successfully prevented by the servomotor load.

Note: The material thickness must not exceed the servo feeder's maximum thickness in order to utilize the aforementioned adjusting procedure. Take caution because the servomotor may get overworked and damaged if the material thickness is greater than the servo feeder's tolerance for thickness.

What Feeder Does FANTY Manufacture?

For a detailed inquiry, pls emails us fanty@sz-fanty.com