Syncing Synergy: Integrating Servo Feeders with Press Machines

In the intricate realm of metal processing, the seamless integration of servo feeders with press machines emerges as a transformative force, redefining precision and efficiency in manufacturing. This comprehensive exploration delves into the key technological aspects, applications, and advantages of syncing the synergy between servo feeders and press machines.

The Power of Integration

Commencing with an elucidation of the critical role that integration plays in modern metal processing, the article highlights how syncing servo feeders with press machines fosters a harmonious workflow, ensuring optimal material handling and processing.

Key Technological Aspects

*Communication Protocols:

Delve into the communication protocols employed in syncing servo feeders with press machines, emphasizing the role of real-time data exchange for precision control.

*Automation Integration:

Explore how automation becomes a linchpin in this integration, facilitating synchronized movements, reducing setup times, and enhancing overall production efficiency.

Applications Across Industries

*Automotive Manufacturing:

Examine how the integration of servo feeders with press machines optimizes the production of automotive components, from body panels to intricate parts, ensuring precision in every step.

*Aerospace Engineering:

Highlight the applications in aerospace engineering, showcasing how the integration ensures the manufacturing of components with stringent tolerances and high precision.

Advantages of Integration

*Enhanced Precision:

Discuss how syncing servo feeders with press machines elevates precision in material feeding, contributing to the production of high-quality components.

*Efficiency Gains:

Emphasize the efficiency gains achieved through integration, reducing downtime, minimizing material waste, and streamlining the overall production process.

Real-Time Monitoring and Control

IoT Integration:

Explore the integration of Internet of Things (IoT) technologies, allowing for real-time monitoring and control of both servo feeders and press machines, ensuring adaptability to dynamic production demands.

Predictive Maintenance:

Discuss how predictive maintenance becomes a reality through integration, minimizing the risk of unexpected breakdowns and optimizing the lifespan of machinery.

What Feeder Does FANTY Manufacture?

These state-of-the-art feeders deliver accurate and coordinated material feeding thanks to sophisticated servo technology. They are the best option for sectors requiring the production of complex parts with tight tolerances.

Roller feeders, with their versatile design, guarantee even and seamless material advancement. Because of its roller-based construction, which lowers friction, they can be used with a variety of materials.

Gripper feeders are designed to reliably feed irregular materials because of its ability to handle complicated shapes. They are especially useful for precision-oriented applications like complex metal shaping.

Zigzag feeders are ideal for high-speed operations because they provide controlled and quick material progress. In industries with rigorous production schedules, they are essential.

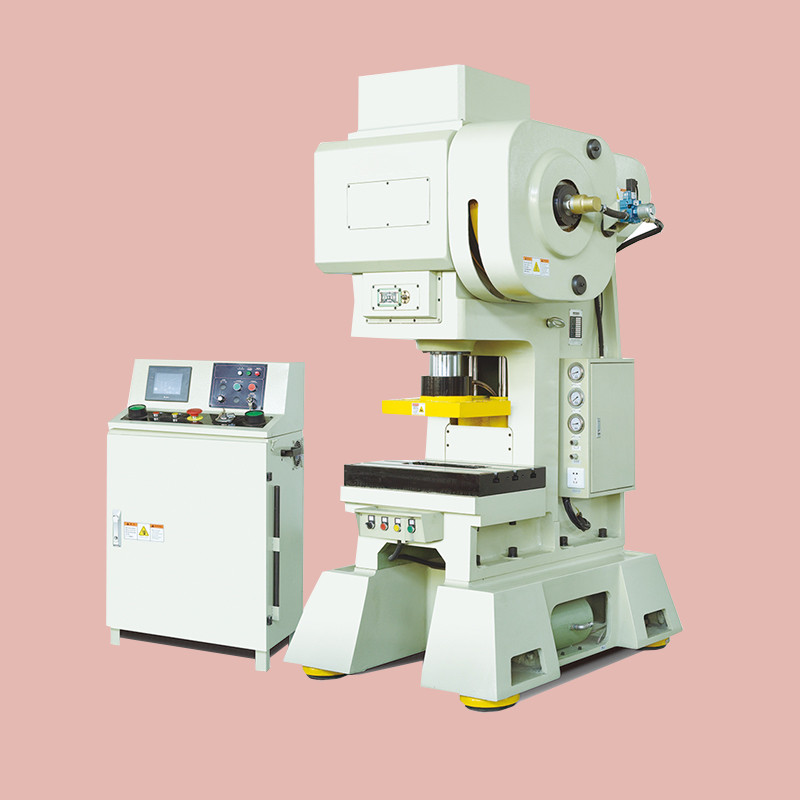

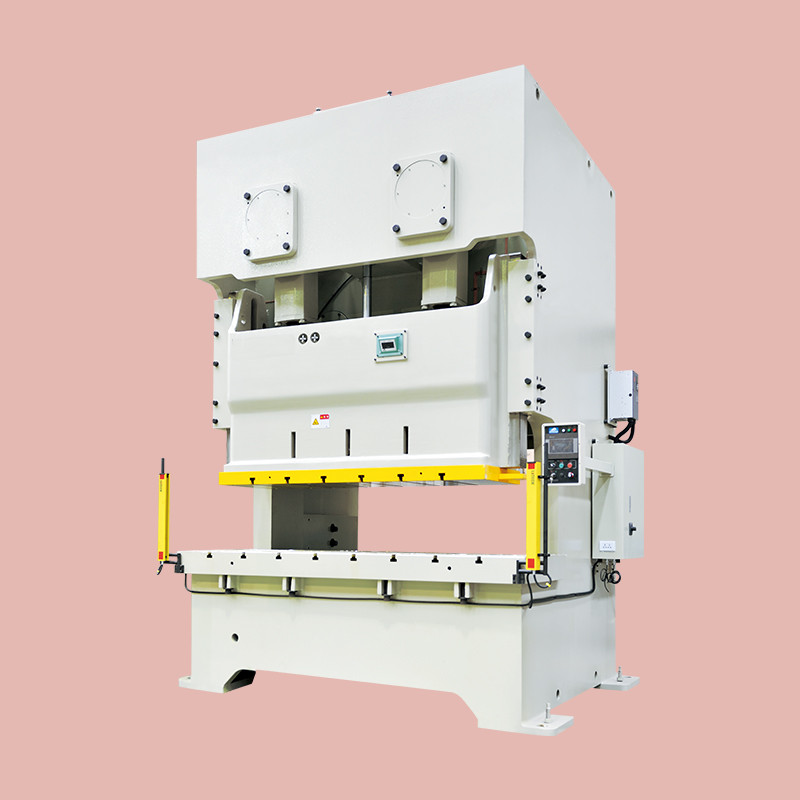

What Press Does FANTY Manufacture?

A specialized mechanical tool that quickly forms and shapes metal sheets during metal stamping operations. Its extraordinarily high stroke rates let it to produce a lot of parts quickly and in great quantities.

A precise instrument frequently used in the metalworking industry to precisely drill holes, notch, and form metal parts. It uses precisely designed tools and dies to provide consistent outcomes with the least amount of material waste.

A robust press system that performs well in jobs requiring high precision metal punching and forging. Its sturdy H-frame construction guarantees precision and stability while it is in use.

Conclusion

As the article concludes, underline the pivotal role of syncing synergy between servo feeders and press machines in elevating precision and efficiency in modern metal processing. Position this integration as a catalyst for advancements in manufacturing, driving the industry toward unprecedented levels of productivity and quality.