How Can Coil Feed Lines Enhance Efficiency in Stamping Processes in 2025?

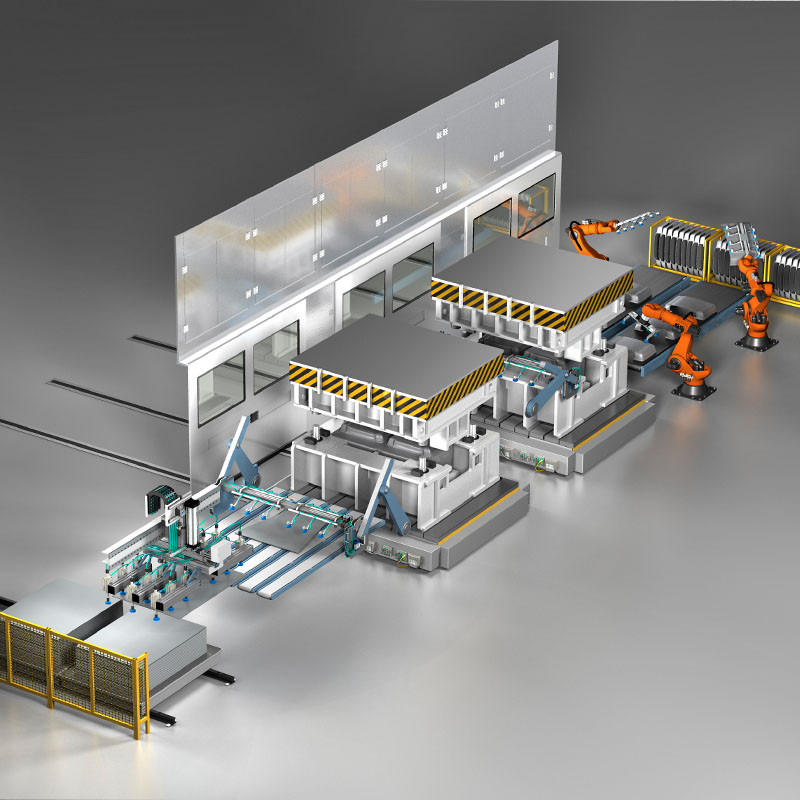

In 2025, coil feed line is integral to enhancing stamping automation systems, which is crucial for improving operational efficiency, reducing waste, and increasing productivity in industries such as automotive manufacturing, electronics, and metalworking. These systems are designed to streamline the feeding of material into stamping presses, ensuring precision and minimizing the need for manual labor. As global manufacturing trends lean toward automation, coil feed lines have become a central focus for companies striving to improve their production processes and reduce operational costs.

Coil feed lines offer significant advantages in metal processing and automated stamping, particularly as industry requirements evolve with the advent of Industry 4.0. By integrating advanced technologies such as servo-driven feeders, coil straighteners, and real-time monitoring systems, manufacturers can ensure a smoother, more efficient production line. This contributes not only to faster throughput but also to enhanced quality control, ultimately improving the overall efficiency of stamping processes.

The Role of Coil Feed Lines in Stamping Automation

The fundamental purpose of coil feed lines in stamping automation.

It is to ensure continuous, reliable feeding of materials into machines. These systems eliminate many of the inefficiencies associated with manual feeding and help manufacturers achieve consistent part production at high speeds.

In 2025, automation in coil feed lines goes beyond just material handling—it’s about precision. Using automated coil feeders and servo-driven systems, manufacturers can achieve a level of accuracy that would be difficult or impossible to replicate manually. This precision significantly reduces the likelihood of errors, such as misfeeds or material jams, which can halt production and increase downtime.

How Coil Feed Lines Contribute to Improved Efficiency

1. Minimizing Downtime

* One of the most significant benefits of modern coil feed lines is their ability to minimize downtime. By using advanced coil straighteners and feed rollers, these systems ensure that the material flows smoothly into the press, reducing the likelihood of stoppages due to material issues.

2. Reducing Waste

* Coil feed lines contribute directly to reducing material waste. With better control over the material feed, companies can reduce the amount of scrap generated during production. These lines ensure that the material is consistently aligned with the stamping process, resulting in minimal waste and improved yield.

3. Improved Material Utilization

* Coil feed lines help manufacturers make the most of their raw materials. Through precise feeding mechanisms and automated adjustments, manufacturers can optimize the material used in each stamping cycle, resulting in more efficient production and lower material costs.

Integrating Coil Feed Lines with Industry 4.0

As Industry 4.0 continues to gain momentum, coil feed lines are becoming smarter. By integrating these systems with IoT-enabled sensors, manufacturers gain real-time insights into the performance of their stamping processes. These insights allow for predictive maintenance, where potential issues are identified before they cause equipment failures, further reducing downtime and improving productivity.

Reducing Human Error with Automation

Another key benefit of advanced coil feed lines is the reduction in human error. These systems remove the variability associated with manual feeding and material handling. With automated coil feeding systems, manufacturers can rely on precision and consistency, allowing them to achieve better quality control and reduce defects.

The Future of Coil Feed Lines in 2025

As the demand for more complex and high-quality stamped parts increases, coil feed lines will continue to evolve. Manufacturers are seeking more sophisticated automation solutions, including the use of AI and machine learning, to optimize coil feed systems further. These systems will continue to improve in precision, speed, and flexibility, ensuring that stamping processes remain at the forefront of manufacturing technology.

With the rising focus on sustainable practices, it’s also important to note that coil feed lines help reduce waste and material consumption, aligning with the broader industry goals of minimizing environmental impact.

Conclusion

As we look to the future of stamping processes in 2025, coil feed lines will remain a key component of stamping automation systems. The ability to streamline material handling, reduce downtime, improve product consistency, and optimize material usage makes them an indispensable part of modern manufacturing operations. For companies looking to enhance their operational efficiency and maintain competitiveness, investing in high-quality coil feed lines will be crucial.