What Are the Key Benefits of Automated Pressing Systems for the Automotive Industry?

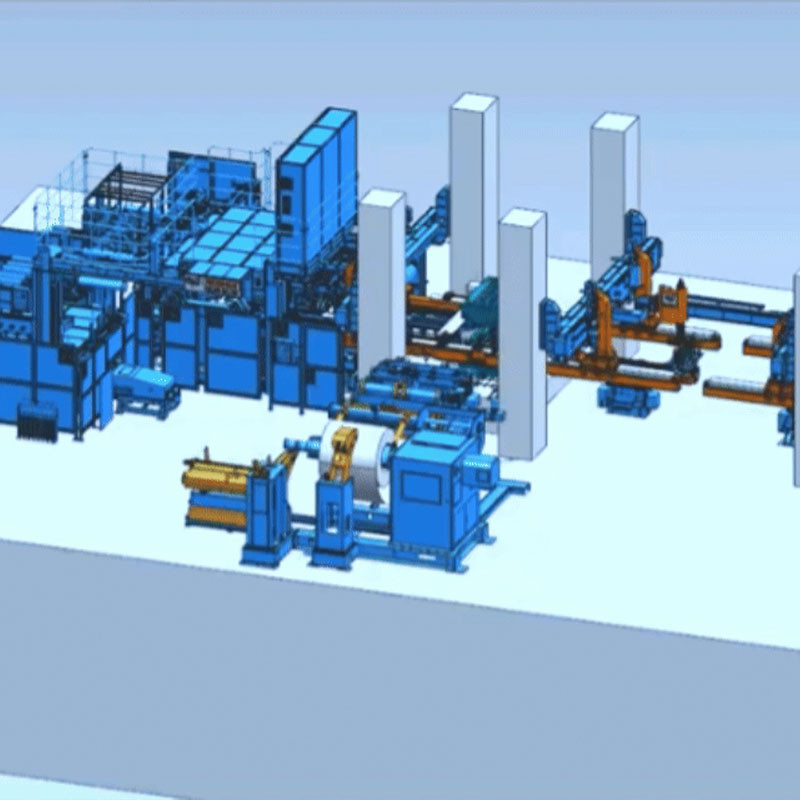

The automotive industry operates in an environment of tight deadlines, high precision, and growing consumer demand for affordable, reliable, and advanced vehicles. Automated pressing systems, also called automated stamping system or Stamping Automation

have become an integral part of modern manufacturing processes in this sector, offering transformative benefits. This article explores the key advantages of automated pressing systems and why they are vital for the automotive industry's future.

1. Enhanced Production Efficiency

Automated pressing systems streamline manufacturing workflows, enabling continuous and faster production cycles. Unlike manual processes, these systems minimize downtime and bottlenecks, ensuring steady output.

Key benefits include:

High-speed operations: Automated systems can handle multiple tasks in a fraction of the time, significantly improving throughput.

Seamless integration: These systems can easily integrate with existing production lines, including feeding and unloading systems, for uninterrupted workflows.

Consistency in output: Automated systems eliminate human fatigue, ensuring uniform results across batches.

For example, stamping processes for automotive parts such as body panels, brackets, and structural reinforcements are performed faster and with greater precision when automation is employed.

2. Improved Accuracy and Quality

In the automotive industry, dimensional accuracy and surface finish are critical. Automated pressing systems use advanced sensors, control mechanisms, and software to maintain precision at every stage of the process.

Benefits to quality include:

Error reduction: Sensors and feedback systems detect and correct issues in real time.

Repeatable results: Every part produced meets the same specifications, reducing the need for rework or scrap.

Superior surface finishes: Automated pressing minimizes defects such as scratches or uneven edges, ensuring top-quality parts.

For instance, intricate components like gear casings and suspension elements require exact tolerances, which automated systems consistently achieve.

3. Cost Savings Through Material Efficiency

Automated systems use advanced programming to optimize material usage, reducing waste and lowering overall production costs.

Material utilization: Automated pressing systems use precise cutting and shaping techniques, minimizing scrap.

Energy efficiency: Many systems are designed with energy-saving technologies, reducing operational costs over time.

Long-term savings: Though initial investment costs may be high, automation reduces labor costs and enhances productivity, offering a favorable return on investment (ROI).

Automotive manufacturers benefit significantly from these savings, especially when dealing with expensive materials like aluminum or high-strength steel.

4. Greater Flexibility and Scalability

Modern automated pressing systems are highly adaptable, making them ideal for manufacturing a wide range of automotive components.

Flexibility in design: Systems can be programmed to produce various shapes and sizes, accommodating evolving vehicle designs.

Quick changeovers: Automated setups enable manufacturers to switch between different tools and dies swiftly, minimizing downtime.

Scalable production: Whether producing small batches or mass quantities, automated systems can adjust to meet demand.

For example, as electric vehicles (EVs) gain traction, automated systems are being used to manufacture lightweight components tailored to improve energy efficiency.

5. Enhanced Workplace Safety

Manual pressing operations often involve risks such as injury from heavy machinery or repetitive strain. Automation significantly reduces these risks by minimizing human involvement in hazardous tasks.

Safer operations: Automated systems handle high-force pressing tasks, keeping workers at a safe distance.

Improved ergonomics: Workers are reassigned to supervisory roles, avoiding physically demanding tasks.

Compliance with regulations: Automated systems help companies meet stringent safety standards, reducing liability risks.

A safer workplace also improves employee morale and retention, which are essential for a stable workforce.

6. Data-Driven Insights for Continuous Improvement

Modern automated pressing systems are equipped with IoT-enabled sensors and monitoring tools that provide real-time data on performance, maintenance needs, and production output.

Predictive maintenance: Monitoring systems detect wear and tear, preventing unexpected downtime.

Performance tracking: Manufacturers can analyze data to identify bottlenecks and optimize processes.

Quality control: Real-time insights allow for immediate adjustments, ensuring consistent part quality.

This data-driven approach is particularly valuable in the automotive industry, where precision and efficiency are paramount.

Conclusion

Automated pressing systems have revolutionized the automotive manufacturing landscape, offering unparalleled efficiency, precision, and adaptability. By integrating these systems, manufacturers can meet rising demand while reducing costs, enhancing quality, and maintaining a safer working environment.

As the automotive industry continues to evolve—embracing trends like electric vehicles and lightweight designs—automated pressing systems will play an even more critical role in ensuring competitiveness and innovation.

Whether you’re considering upgrading your manufacturing line or looking to adopt automation for the first time, the benefits of automated pressing systems make them a worthwhile investment.

For more insights into stamping automation solutions and the latest advancements, feel free to explore our website.