How Should I Pick a Feeding Equipment for Automatic Coil Material Processing?

As a type steel coil handling equipment, A typical device used is the feeder machine. As the press feeder, also called coil feeder, It is a piece of essential machinery for both light and heavy industries. The manufacture of metal chains, miniature washers, and EI lamination all make extensive use of the high-speed feeder machine. Your needs might be met by one of four high-speed press feeders. There are numerous feeder machine manufacturers at the moment, and it sometimes happens that the price differences between feeders are extremely significant, which causes clients a great deal of difficulty when making purchases. How can I get the cheapest price of them?

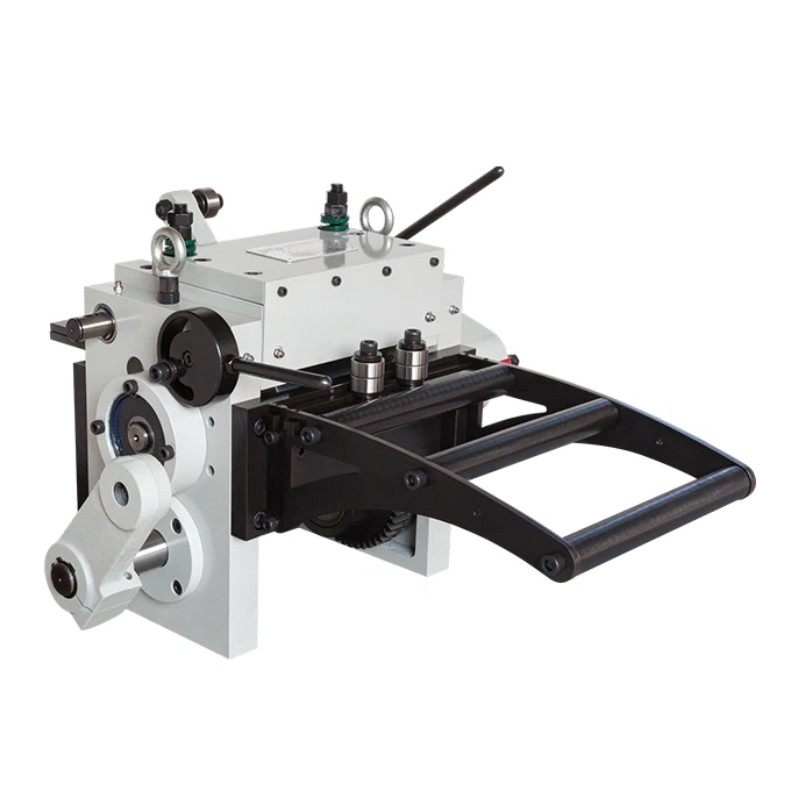

The two most often utilized feeding devices for the automatic processing of coil materials are roller feeder and NC servo feeder.

Only the output shaft of various types of punching machines can be used with the roller feeder. Both the feeding step and width have severe restrictions. Typically, the roll feeder cannot be chosen if the material width is higher than 500mm or the feeding step is greater than 300mm.

The roller feeder does, however, have some benefits as well. For example, it has a high-speed model and can feed at a maximum rate of 500 times per minute with a high-speed punch.

The NC servo feeder can be utilized with a variety of processing tools, including hydraulic punch presses, shearing machines, laser cutting machines, etc. in addition to all types of punching machines. The degree of customization is significant and the feeding width and step distance are both limitless. Proportional roller feeding is used. The gadget should be large.Due to the servo motor's slow response time, the NC servo feeder is ineffective for high-speed feeding.

The benefits and drawbacks of a roll feeder and a nc servo feeder are different. Customers find it challenging to distinguish between the two. How can they select a feeder machine that will work for their particular production?

1. The thickness of the material determines the type of NC servo feeder. According to the thickness of the material, there are now three varieties of NC servo feeder made in China: thin plate 0-2.2mm, medium plate 0-3.2mm, and thick plate 0-4.5mm. Accordingly, the cost rises according to the thickness that may be attained.

2. Determine the appropriate mechanical or pneumatic relaxing method based on the equipment's corresponding speed. Through the scaling of the cylinder fixed to the inner wall of the feeder, the pneumatic NC servo feeder achieves the compression and relaxation of the roller group. When in operation, it can be combined with additional machinery. For example, it can be used with a shearing machine to produce material blanks in addition to punching machines for feeding and punching. However, pneumatic relaxation has a rather slow reaction time, making it unsuitable for high-speed, short-step feeding production.