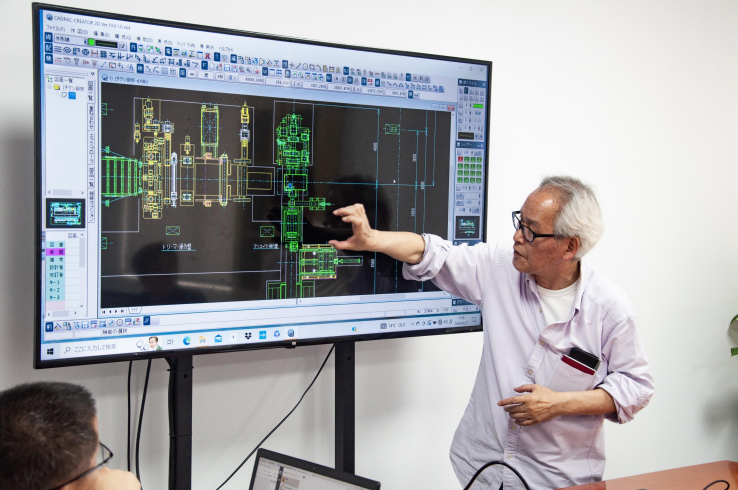

- Equipments Manufacturer

Over 10 years as a manufacturer of metal stamping automation equipments with 80+ R&D Team.

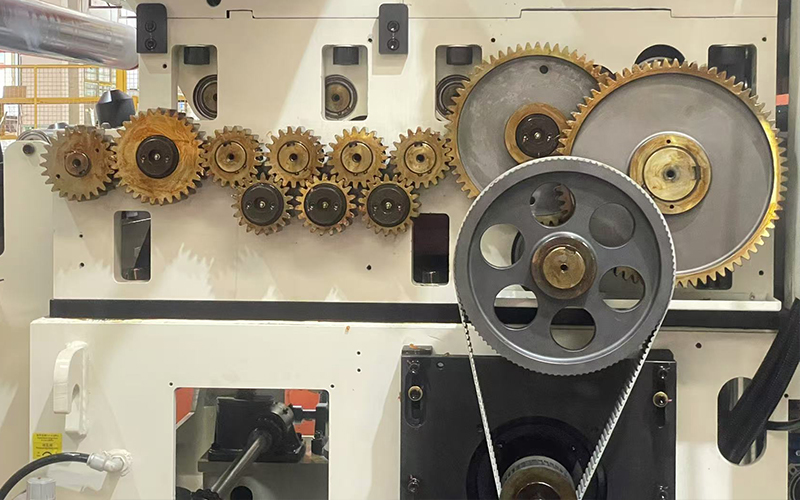

Rollers are heated to high temperatures (typically 850–950°C) and then rapidly cooled (using oil, air, or water). The cooling medium and rate directly affect the hardness and microstructure.

After quenching, tempering is performed to reduce internal stresses, enhance toughness, and refine the microstructure. Precise control of tempering temperature (e.g., 150–200°C) is crucial to achieve the desired hardness.

For applications requiring surface hardness with a tough core, induction hardening can be used. This technique heats only the roller surface using high-frequency currents, achieving the required hardness while retaining the core's toughness.

The choice of cooling medium (oil, water, or air) and the cooling rate must be carefully controlled to avoid cracking or excessive distortion.

Cryogenic Treatment: Improves the stability of martensitic structure, enhances hardness, and reduces dimensional changes.

Surface Coating: For added wear resistance, techniques like chrome plating or PVD coatings can be applied after hardening.

Post-heat-treatment hardness testing is essential to verify uniformity across the roller’s surface and ensure that the hardness falls within the HRC60 ± 2 range. Multiple-point testing using a Rockwell hardness tester is recommended for consistency.

Over 10 years as a manufacturer of metal stamping automation equipments with 80+ R&D Team.

Provides various metal stamping automation solutions for our customer.

The pursuit of producing high-quality metal stamping automation equipments. Visit our Factory !