Decoiler Straightener for 0.3~3.2mm Steel

Steel handling in manufacturing processes demands precision and efficiency, especially when dealing with thin steel sheets ranging from 0.3mm to 3.2mm in thickness. The utilization of a decoiler straightener machine becomes indispensable as steel coil handling equipment in such scenarios, streamlining the production process while ensuring optimal material handling. This article provides a comprehensive overview of GL Model decoiler with straightener machines, their functionalities, advantages, and applications in various industries.

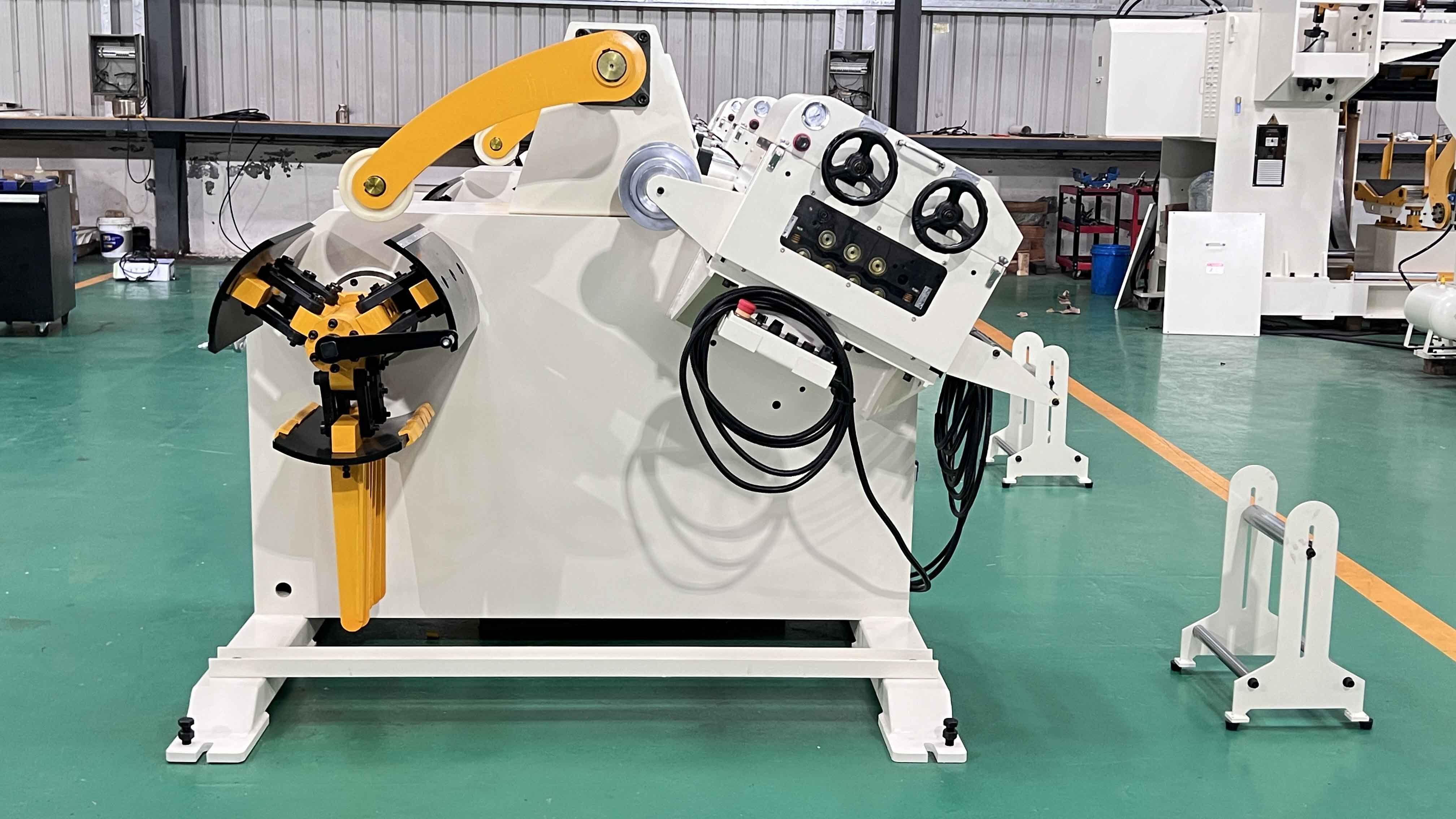

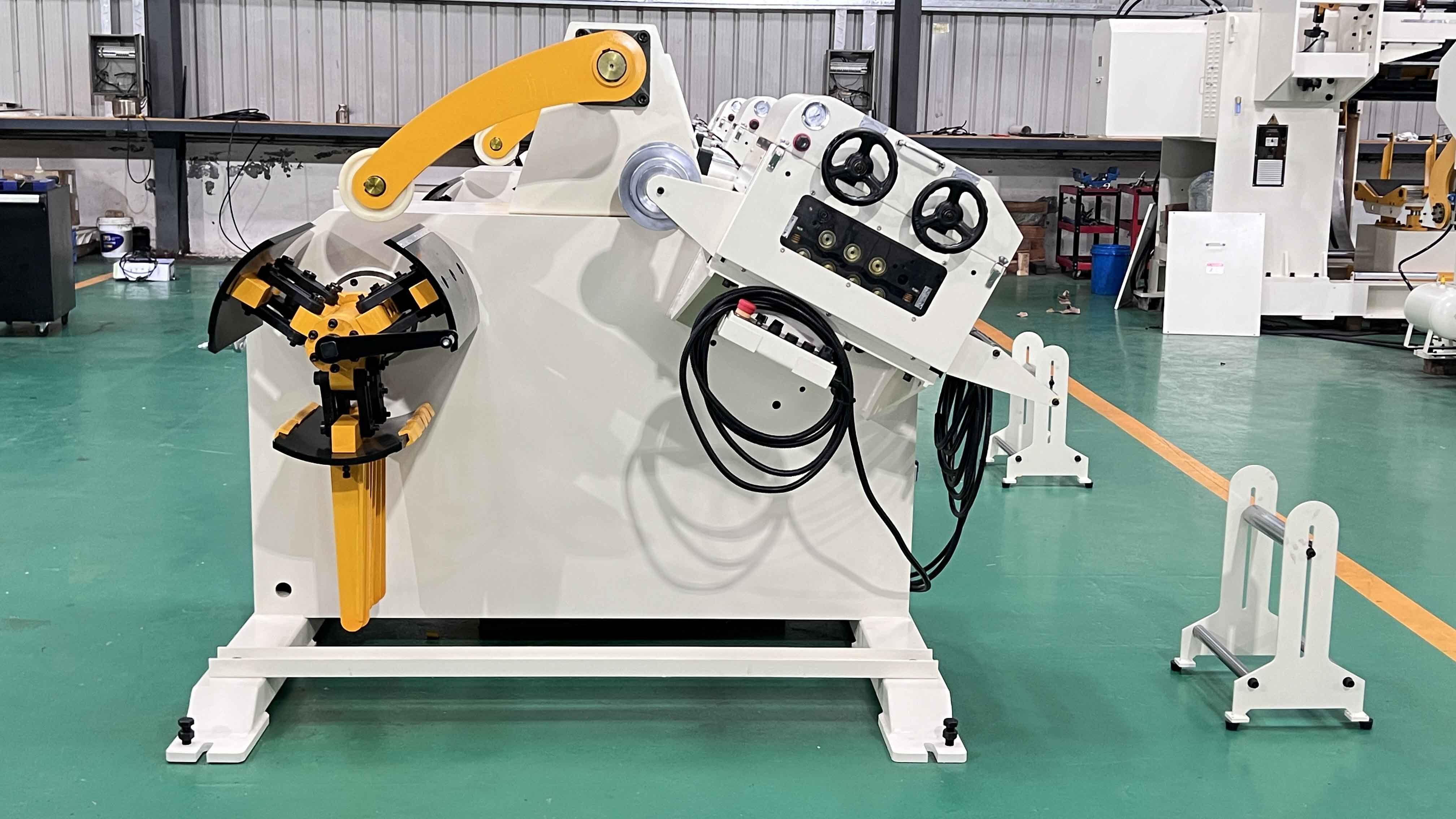

Introduction to GL Model Decoiler Straightener Machine

As the steel coil handling equipment, the GL Model Decoiler with straightener machines are integral components in metal processing industries, facilitating the handling of coiled steel sheets with precision and accuracy. Combining the functionalities of a decoiler and a straightener into a single unit, this steel coil handling equipment effectively flatten and straighten steel coils before feeding them into downstream processes. It can handle thickness 0.3mm to 3.2mm steel coil

The Specification of GL Type Decoiler Starightener

Coil Width: 200~600mm

Coil Thickness: 0.3~3.2

Coil O.D.(mm): Ø 460-530

Coil I.D.(mm): Ø 1200

Max. load(kg): 800~1000

Fanty Machinery GL Model Decoiler Straightener for Sale

1 products found

ViewShowcase

Coil Decoiler Straightener is also called uncoiler cum straightener machine.

Features and Functions of GL Model Decoiler Straightener Machine

Automatic Feeding Mechanism

Decoiler straightener machines feature automatic feeding mechanisms that ensure consistent and uninterrupted material supply to production lines. This automated process reduces manual intervention, minimizing the risk of errors and improving overall efficiency.

Precision Straightening Capability

With precision straightening capabilities, these steel coil handling equipments can achieve tight tolerances and maintain uniform flatness across the entire length of the steel sheets. Advanced control systems enable real-time adjustments, allowing operators to achieve the desired level of flatness and surface quality.

Coil Loading and Unloading Systems

Decoiler straightener machines are equipped with efficient coil loading and unloading systems, facilitating quick and easy changeovers between different coil sizes and materials. This versatility enhances operational flexibility and reduces downtime during setup and maintenance.

Advantages of Using Decoiler Straightener Machine

Increased Efficiency in Production Lines

By eliminating manual handling and optimizing material feeding processes, decoiler straightener machines significantly increase the efficiency of production lines. Faster setup times, reduced scrap rates, and consistent output quality contribute to higher productivity and lower operating costs.

Reduced Material Waste

The precise leveling and straightening capabilities of decoiler straightener machines minimize material waste by ensuring maximum material utilization and minimizing scrap generation. This leads to cost savings and environmental benefits, making these machines sustainable solutions for metal processing industries.

Improved Product Quality

The accurate control of flatness and surface quality provided by decoiler straightener machines results in improved product quality and consistency. Manufacturers can meet stringent quality standards and customer requirements, enhancing their competitiveness in the market.

Applications of GL Model Decoiler Straightener Machine

Automotive Industry

In the automotive industry, decoiler straightener machines are used for manufacturing various components, such as body panels, chassis parts, and structural reinforcements. The precise leveling and straightening of steel sheets ensure dimensional accuracy and structural integrity in automotive assemblies.

Appliance Manufacturing

In appliance manufacturing, decoiler straightener machines play a crucial role in producing components for household appliances, including refrigerators, washing machines, and ovens. The ability to handle thin steel sheets with precision enables manufacturers to meet tight tolerances and design specifications.

Construction Sector

In the construction sector, decoiler straightener machines are utilized for fabricating structural components, roofing materials, and facade elements. The uniform flatness and surface quality achieved through straightening ensure stability and durability in construction projects, enhancing overall safety and performance.

Maintenance and Safety Practices

Regular Inspection and Lubrication

To ensure optimal performance and longevity, decoiler straightener machines require regular inspection and maintenance. Lubrication of moving parts, checking for wear and tear, and calibration of control systems are essential maintenance tasks that should be performed according to manufacturer recommendations.

Safety Features and Protocols

Safety is paramount in metal processing environments, and decoiler straightener machines are equipped with various safety features and protocols to prevent accidents and injuries. Emergency stop buttons, safety guards, and interlocking systems ensure operator safety during machine operation and maintenance activities.

subscription

Or send us messages online !

- *Tel

- *Title

- *Content