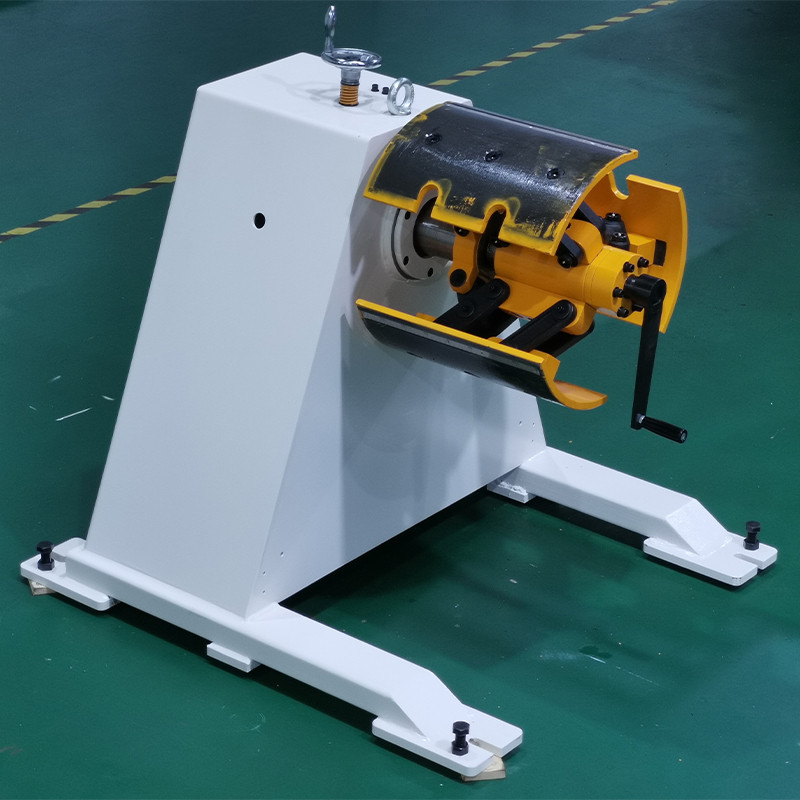

Manual Decoiler

In the intricate landscape of industrial machinery, the Manual Decoiler, as one of the decoilers, takes center stage as a versatile and hands-on solution for material handling in precision stamping lines. This article delves into the essence of Manual Decoilers, defining their role, outlining key features, exploring this type decoiler machine applications in stamping lines, and addressing pivotal concerns that resonate with industry professionals seeking control and adaptability.

What is a Manual Decoiler?

A Manual Decoiler is a straightforward yet effective material handling machine designed for the controlled unwinding and feeding of steel coils. Unlike automated counterparts, this decoiler machine places control directly in the hands of the operator, offering a hands-on approach to material handling in precision stamping applications.

Fanty Machinery Manual Decoiler for Sale

6 products found

ViewShowcase

As decoiler machine, this type manual decoiler machine is designed for unwinding 500mm width steel coil.

A Manual Decoiler is a practical and cost-effective solution within the realm of coil handling equipment.

A Manual Decoiler is a practical and cost-effective solution as a type of uncoilers.

The Manual Sheet Metal Decoiler is a reliable and cost-effective decoiler machine designed for small-scale steel coil handling tasks

The Decoiler Machine For Sheet Metal Unwinding is a reliable and cost-effective decoiler machine for coil handling tasks.

A Manual Steel Coil Handling Decoiler is a cost-effective solution as a Coil Handling Equipment. Now the decoiler for sale.

Key Features of Manual Decoilers

Operator Control: The defining feature is the manual control provided to operators, allowing them to regulate the unwinding process based on real-time observations and adjustments.

Versatility: These Decoilers showcase adaptability, handling various coil specifications, materials, and thicknesses, making them suitable for diverse stamping line applications.

Simple Design: These decoilers are characterized by a simple and user-friendly design, making them accessible for operators with varying levels of expertise.

Cost-Effective Solution: These Decoilers are often a cost-effective option, particularly for small to medium-sized production runs, providing an efficient solution without the complexity of automated systems.

Applications in Stamping Lines

Manual Decoilers find applications in a range of stamping lines, particularly in settings where production volumes are moderate, and operators benefit from direct control over the unwinding process. Industries such as custom fabrication, prototype development, and small-batch manufacturing often leverage the versatility of Manual Decoilers.

Customer Concerns and Solutions

Operator Control and Precision: Operators seek direct control over the unwinding process. Manual Decoilers empower operators to make real-time adjustments, ensuring precision in material feeding and adapting to the nuances of different materials.

Versatility in Material Handling: Clients with diverse material requirements appreciate the adaptability of Manual Decoilers. This type decoiler machine handles various coil specifications, materials, and thicknesses, providing a versatile solution for different stamping line applications.

Ease of Use: User-friendly design is a priority. Manual Decoilers feature a simple and intuitive design, making them accessible to operators with varying levels of experience, reducing the learning curve.

Cost-Effectiveness: In scenarios where automation might be excessive, cost-effectiveness is key. Manual Decoilers offer an efficient solution for small to medium-sized production runs, providing the necessary functionality without unnecessary complexity.

Conclusion

In conclusion, the Manual Decoiler emerges as a practical and cost-effective solution, placing precision in the hands of operators. For industries prioritizing control, versatility, and cost-conscious material handling solutions in their stamping lines, investing in Manual Decoilers is a strategic move toward operational flexibility. Elevate your stamping processes with the hands-on precision of our reliable Manual Decoiler machine technology, where control meets adaptability.

subscription

Or send us messages online !

- *Tel

- *Title

- *Content