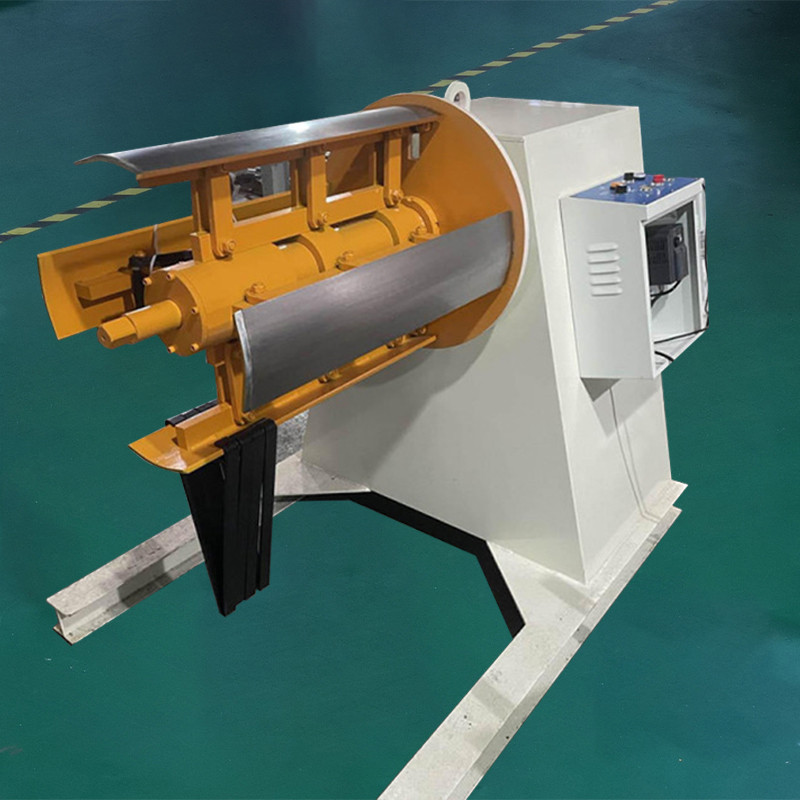

Heavy Duty Decoiler

In the robust landscape of industrial steel coil handling equipment, the Heavy Duty Decoiler stands tall as a powerhouse, meeting the demands of high-stakes material handling in precision stamping lines. This article delves into the intricacies of Heavy Duty Decoilers, defining their essence, outlining distinctive features, applications in stamping lines, and addressing critical concerns that resonate with discerning industry professionals.

What is a Heavy Duty Decoiler?

A Heavy Duty Decoiler is an industrial-grade steel coil handling equipment specifically engineered to handle large and heavy steel coils with unwavering strength and stability. This heavy weight champion in material handling ensures the seamless unwinding and feeding of substantial steel coils, a crucial function in industries demanding high-capacity stamping operations.

Fanty Machinery Heavy Duty Decoiler for Sale

3 products found

ViewShowcase

Heavy Duty Motorized Decoiler is an advanced type of decoiler machines. It works as a Heavy Duty Decoiler

The Hydraulic Expansion Heavy Duty Decoiler is an advanced type of Motorized Decoiler. It is the uncoiler machine

As uncoiler machine, this hydraulic decoiler machine suits for 2 tons above steel coil weight.

Key Features of Heavy Duty Decoilers

Robust Construction: Heavy Duty Decoilers are characterized by robust and durable construction, capable of withstanding the demands of heavy and large coils without compromising performance.

High Weight Capacity: This decoiler machine is designed with significantly higher weight capacities compared to standard models, allowing for the efficient handling of large and heavy materials.

Advanced Coil Control: Heavy Duty Decoilers incorporate advanced coil control mechanisms, ensuring precision and stability in the unwinding process, even when dealing with oversized coils.

Adaptable Coil Handling: While robust, this decoiler machine maintains adaptability, handling a diverse range of coil specifications and materials with ease.

Applications in Stamping Lines

Heavy Duty Decoilers find their niche in industries that demand substantial material handling capabilities, such as shipbuilding, construction, and heavy machinery manufacturing. This type decoiler machine plays a pivotal role in stamping lines where large and heavy coils are integral to the production of oversized components.

Customer Concerns and Solutions

Robustness and Durability: Clients prioritize robustness and durability in heavy-duty applications. Our Heavy Duty Decoilers are engineered with high-strength materials and reinforced structures, ensuring longevity and reliability in demanding industrial environments.

High Weight Capacity: Industries with heavy coil requirements seek machines with impressive weight capacities. Our Heavy Duty Decoilers are designed to handle substantial weights, providing a solution for the efficient handling of large and heavy coils.

Precision in Unwinding: Precision is paramount, even in heavy-duty applications. Advanced coil control mechanisms in our Heavy Duty Decoilers ensure a controlled and stable unwinding process, contributing to the precision of downstream stamping operations.

Adaptability to Various Materials: Versatility in material handling is crucial. Our Heavy Duty Decoiler machine is adaptable to various coil specifications and materials, offering a comprehensive solution for industries with diverse material requirements.

Conclusion

In conclusion, the Heavy Duty Decoiler machine emerges as a formidable player in the realm of industrial material handling, catering to the unique demands of heavyweight coil applications. For industries seeking strength, durability, and precision in their stamping processes, investing in Heavy Duty Decoiler is a strategic move towards operational excellence. Elevate your heavy-duty stamping operations with our robust and reliable Heavy Duty Decoiler technology, where power meets precision.

subscription

Or send us messages online !

- *Tel

- *Title

- *Content